Barbecue made of bricks with your own. How to make a barbecue oven with your own hands from brick: step-by-step instructions. Garden combi stove body

Before you start building a brick barbecue with your own hands, you should make drawings and use them to calculate the amount of building materials needed. In this case, the scheme must be created independently, since there are no universal barbecue designs.

Drawing up an action plan

During construction, you must follow the general instructions that apply to any type of barbecue:

- the grill should be made at least 70-80 cm, taking into account the height of the owner;

- the stove is traditionally located 10 cm below the grill level;

- a niche for firewood and cabinets, and a hook for tongs should be provided.

In this case, everything must be taken into account small parts so that later it would be convenient to use the structure. When the drawings are ready, you should make calculations, draw up an action plan and prepare a list building materials(including for the foundation).

The list of materials for main work should include:

- fireclay and facing bricks;

- clay and ordinary mortar;

- metal rod d-30 mm;

- steel sheet 5 mm;

- doors for the firebox and ash pan;

- grate.

And for arranging the base:

- construction mixture;

- reinforcing bars;

- boards for formwork construction;

- crushed stone and sand.

The construction of the furnace takes place on a slab base, the frame is erected from fireclay bricks. After which it is lined with stone. Granite, sandstone, dolomite, and rubble stone are suitable. You can show your imagination and give the fireplace any fancy shape.

Why brick?

Very often, barbecues and barbecues for dachas are created from scrap materials: barrels and, a little less often you can see welded structures (from the simplest to artistic casting). It is much less common to make a brick barbecue with your own hands. Many are convinced that they are practically no different from portable structures.

But the heat distribution pattern in brick structures is completely different. The heat from the coals in open barbecues is directed upward, making heat treatment only one side of meat. Therefore, during processing, it is necessary to periodically turn the product to the other side to ensure even frying.

The brick structure of the barbecue acts like an oven, only without the door. Warmth reflecting off him inner surface, acts simultaneously on the entire surface of the product, ensuring its uniform processing.

This greatly improves taste qualities dishes, makes them more juicy and tender.

In this regard, the following advantages of a brick barbecue compared to a metal barbecue can be noted:

- uniform processing of food;

- the ability to build complex structures with additional hob, smokehouse, grill and sink;

- a barbecue can be made one of the most attractive parts of the site.

How to make a garden barbecue

Like any other structure, a barbecue for a summer residence is built on a foundation. The pavilion should fit harmoniously into the design of the site. Since such a pavilion will be used year-round, it is better to build garden type hearth.

The construction of the fireplace must comply with basic safety regulations; the chimney must be installed on the roof. The construction of such a structure has a rather complex technology. Externally and functionally, it is a fireplace that is used for decoration. interior design dachas

Thematic material:

A gazebo or pavilion with a fireplace can be styled as a fairy-tale hut for receiving guests or arranged as summer house with kitchen utensils, dining furniture, sofa and TV. If the barbecue is located in a pavilion, it is better to entrust its construction to specialists, but if you have a little experience, you can try to build it yourself.

The basis of the elementary design of a barbecue is a quadrangular frame; coal is placed in it, over which a grate is placed. It is advisable to make a structure such as a fireplace multifunctional: build a firewood rack at the bottom, a dish rack above it, a barbecue itself above it, and a smokehouse can be located above it.

In this case, the structure will be multi-story. You should decide what the design of the future fireplace for the dacha should be, and then make drawings and outline a construction plan.

Barbecue options

When considering brick barbecue projects, sometimes there is a desire to supplement the drawings with your own elements in accordance with personal preferences. Some future owners, when building a brick barbecue with their own hands, equip it with an additional grill and stove.

Barbecues can be very diverse:

- barbecue fireplace;

- barbecue grill;

- multifunctional building;

- barbecue with one hearth;

- barbecue with grill and cauldron;

Additional accessories for such furnaces are very diverse. For example, oven, spit, tandoor, cauldron and others. Among complex structures There are hand-made and prefabricated ones.

An interesting idea - a complex. Permanent structures can be built as a three-story structure. Semi-finished products are placed in the chamber on grates or suspended. For cold smoking, a brazier with coals and a baking sheet with wood chips are placed inside the chamber, and for hot smoking, logs of the appropriate types of wood are placed in the firebox.

This smokehouse has only one drawback: it strongly absorbs odors. Therefore, if you process meat after fish, it will acquire a specific smell, and sometimes even a taste. In this case, it is better to make this device from iron.

Construction of a brick barbecue

The positive aspects of installing a barbecue stove are its decorative appearance and functionality. It is better to install such a structure not on outdoors, but in a pavilion or summer kitchen.

Let's consider step by step plan construction of a barbecue for a summer residence.

Step 1: Arrangement of the foundation

Initially, a site for construction is selected. When placing a barbecue in a building, it is necessary to prepare a foundation for it. Together with it, a base for a barbecue oven is made; it is similar to a slab foundation.

The pit is made 0.3 m larger than the dimensions of the structure, and about a meter deep. The formwork is installed and a sand and gravel “cushion” is laid on its bottom. It is covered with the first layer of mortar (0.2 m), and then steel rods are laid like a lattice. From the end of pouring until the solution completely hardens, 1-3 weeks should pass.

Step 2: Preparation

Before starting construction, you should select building materials for construction. It should be remembered that for the construction of a furnace, two types of bricks are needed: the main refractory one and for cladding. At the same time, only fireclay bricks that are resistant to high temperatures are laid in the firebox area, which also has excellent heat-saving qualities and long-term heat transfer. And as a exterior finishing A standard refractory grade of brick is acceptable.

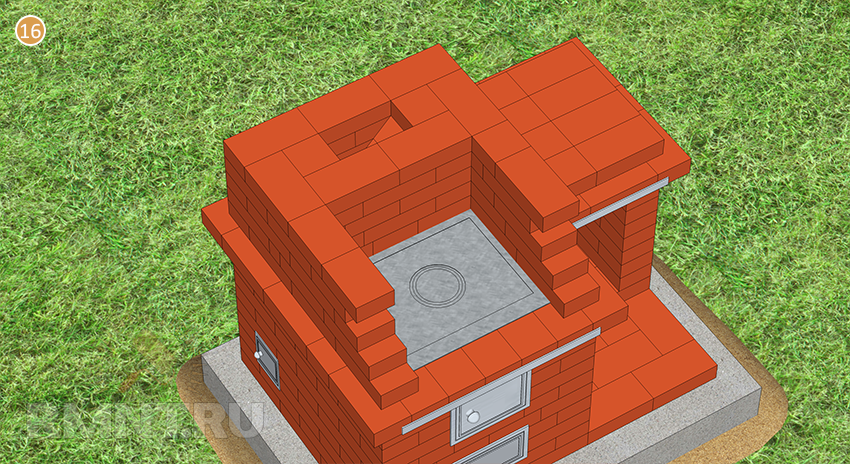

Step 3: Construction

In the construction of the structure, an ordering scheme is used (see below). It takes into account the usual brick dimensions - 230*114*65. For the firebox and stove, bricks should be laid only with clay mortar, and in places not in direct contact with fire, ordinary bricks are allowed to be used.

Pre-mixed fireclay mortar requires red clay, cement, sand and water.

Step 4: Firing

After the stove is erected, firewood or coal is placed in the firebox and barbecue and then set on fire. This is necessary for firing the inner surface of the furnace walls. The heat is brought to the maximum possible.

This is one of the most functional stoves for a summer residence. For small areas, a simplified scheme is suitable. When choosing the type of garden barbecue, you need to take into account all its parameters: functionality, size, location on summer cottage. For the convenience and durability of the structure, it would be advisable to build a gazebo or pavilion.

Step 5: Drying

After heating the oven, the next step is drying. It should be carried out in the summer in clear weather - at least 5 days, and in the fall in cloudy weather - up to 20 days. In this case, it should be covered from possible rain with a protective film.

The final stage will be decorating the stove. The bricks should be freed from excess mortar and applied in the right places paint to highlight the seams. After which the barbecue oven is completely ready for its intended use.

Filimonov Evgeniy

Reading time: 8 minutes

A A

How to build a brick barbecue. Stages of work. Decorative design. Preparatory work. Instructions for laying.

Having own plot, you always want to spend time usefully, for this purpose a brick barbecue will not be superfluous. To build it, you need to know how to lay the foundation correctly. Which decorative designs use. What are the differences between a grill and a barbecue?

The main stages of building a barbecue. Required preparatory work. How bricks are laid. Basic nuances of masonry. Recommendations and tips for reliable and durable construction.

A metal grill is definitely good. But, in addition to functionality, you also want beauty, especially on the site: in the country or near the house. A brick barbecue gives an attractive look without reducing functionality. There are absolutely simple models, which can be put together, even without skill, in a day or two; there are more complex ones - entire complexes. We don’t recommend building these without experience, but try a simple barbecue oven or just a brick grill. Master masonry and basic techniques, and then you can take on more serious projects.

There is no exact division between grills and barbecues. The main difference is that barbecue is cooked on skewers, while barbecue is cooked on a grill. But both of these cooking methods can be used even over a fire, so - for us, at least - both the grill and the barbecue are one design.

You can also classify by the presence of a roof. A barbecue is always an open device, without a chimney. In barbecues, especially those made of brick, chimneys are often made, although there are also simple open models.

Simple brick grill

This design is very simple and can be easily modified to suit any needs and desires. It consists of brick walls in which projections are arranged (the brick is placed on its edge). Heat-resistant sheets (metal, etc.), grates, and skewers are placed on these protrusions. Convenient, especially if there is some kind of roof over your head in case of precipitation, but it is built separately and at will.

Any brick structure requires a foundation, or at least a prepared foundation. Not even this small brick grill. Since there are not many bricks - the wall is half a brick, then for this the design will suit a compacted area lined with some kind of hard surface.

Preparing the base

Remove the fertile layer and, if necessary, deepen the pit. The depth should be about 20-25 cm. The dimensions of the foundation or platform are 50 cm larger than the dimensions of the stove in all directions. The bottom is leveled, crushed stone of the middle fraction is poured onto it. The thickness of the crushed stone layer is 15 cm. It is compacted well. It is advisable to use a vibrating plate, if not, a metal or wooden tamper.

Further steps depend on the selected base. If this is one of the coverings - paving stones, paving slabs and similar materials, then a layer of fine-grained sand is poured into which the coating is laid level.

If selected as a basis slab foundation, it is reinforced with a rod 10 mm in diameter. It is laid along and across the foundation in increments of 20 cm, and tied at the intersection. If you don’t know how to knit with special wire, you can tie it with plastic clamps. Reinforcement is allowed for this model finished mesh made of thick wire. The formwork is placed around the edges and everything is filled with M250 concrete. Work can begin in a week if average daily temperature was not lower than +20°C, and after two if it was +17°C.

Brick barbecue with pipe: order

For this brick barbecue use full-bodied ceramic brick M200. You can use a stove-type one, but it’s more expensive; you shouldn’t use fireclay: it’s not the right temperature and it doesn’t like moisture too much to feel normal in an open grill.

The masonry is laid using a clay-sand mixture, to which a little cement is added for greater strength. For beginners it is better to take ready mixture for stoves, but not heat-resistant, without fireclay. Knead according to the instructions, seam thickness is 3-5 mm, maintain strictly. Constantly monitor the verticality of the walls and the horizontality of the masonry. This is important for normal operation of the oven.

Every odd row starts with a whole brick, odd - with a half. In the 6th and 10th rows, the bricks are placed on a spoon - sideways, and turned across the main masonry. If you are making a barbecue - under a grate - in the same rows the back wall is made of bricks, also placed on spoons, and to maintain the thickness of the masonry they are placed in two rows, just like the rest - with bandaging - displacement of the seams. If you are going to use the grill as well - for skewers - on the back wall you also place a brick on a spoon, making a ledge in this area as well. In front, a profile is used as a support for skewers. metal pipe small sections, cut to size. You can make recesses in it for skewers.

Starting from the 7th row, the laying is carried out only on half - right or left - as is convenient for you, but this layout is given under the frying chamber on the left - it is wider, and there is a table on the left. If it’s more convenient for you the other way around, do a mirror image of this order.

Brick is a hygroscopic material; in order to reduce the amount of moisture that it will “pull” from the base and extend its service life, waterproofing is needed under the first row. Can be laid in two layers roll material(such as roofing felt or waterproofing), walk around the perimeter hydrophobic impregnation. A layer of waterproofing between the first and second rows would not hurt either.

This barbecue option is a little more complicated, but also not the most difficult. The most important thing is that the combustion chamber here has a direct arch, and it is much easier to make it with a vaulted one. The brick frying chamber is raised to a height of 90 cm, the total height - to the beginning of the pipe - is 217.5 cm.

It all starts with preparing the foundation. For this barbecue oven, only a monolithic reinforced base (reinforcement step 15 cm) on a compacted crushed stone base is suitable. Waterproofing is spread in two layers on the dried foundation, then masonry begins. If the barbecue is made in a gazebo, the first row of masonry should begin at floor level.

The first 9 rows do not require any special explanation. Lay exactly according to the plan, maintaining order, using halves and cut bricks, if indicated on the plan. Be sure to check the verticality of the resulting walls, as well as control the thickness of the mortar - 8-10 mm and the horizontal laying of each brick.

To control the thickness of the seam, you can use a reinforcement bar of the appropriate diameter. It is placed on the edge, the surface of the row is filled with mortar, and the excess just above the rod is cut off with a trowel. After laying and tapping the bricks, it turns out straight seam- the rod prevents the brick from falling lower than necessary. The rod is then removed and placed higher.

To be able to lay the 6th row (solid), after laying the 5th, lay a strip of metal 4-5 mm thick, 40 mm wide. The length is slightly less than the furnace span - 1450 mm. 3 stripes are needed - one at the edge, two approximately in the middle of each row of bricks

The light color in these rows indicates fireclay brick (ША-8). Place it on the same composition of clay and sand (a small proportion of cement can be added). It is better not to use chamotte-based mixtures: they require very high temperatures for sintering, which are unattainable in outdoor barbecues. As a result, this solution may subsequently simply crumble.

The formation of the arch continues, which in the 30th row turns into chimney. Next, alternate the 30th and 31st rows until the required height is reached.

If you often spend time with friends, love meat or fish, then you simply need a brick barbecue. This functional feature will allow you to cook even large pieces of meat, turning them into a delicious, aromatic dish. We invite you to get acquainted with the design features of detailed buildings and the sequence of their construction.

Design and principle of operation of a brick barbecue

Modern complexes usually include more than three fireboxes. Their dimensions are determined at the project development stage. This device makes the barbecue oven multifunctional. A Russian stove with an oven, a brick barbecue, and a smokehouse are provided. There are other possible options. There are three or more channels, which, thanks to the valve system, can be isolated from each other.

The barbecue includes a grate installed 20-25 cm below the level of the side walls. The coal tray is solid, which provides sufficient draft. The coal smolders, so there is gradual, uniform cooking of various dishes. The height of the walls ensures the formation of a warm air-smoke cushion, due to which the prepared food acquires a characteristic smoky aroma.

Where is the best place to organize a barbecue area?

When choosing a barbecue location, take into account whole line factors. It should be located:

- away from flammable substances;

- away from trees;

- on the leeward side of buildings;

- far away from .

It is advisable to locate the complex away from the house (at a distance of at least 5 m). At the same time, at a minimum distance from the kitchen, so that the housewife can cook comfortably. It is advisable to pave the complex using either brick. All wooden elements coat with fire retardant.

Types of ready-made brick barbecue kits for a summer residence

When you decide to purchase a ready-made brick barbecue set for your dacha, pay attention to the barbecue stove:

- "Sadovaya". Suitable for year-round use. Consists of eight elements and steel pipe. Mounted on . With a height of 1.8 m, it has dimensions of 1×0.8 m;

- "Prestige". Weighs 600 kg. With a height of 2.4 m, it has dimensions of 1.3 × 1.05 m;

- "Picnic". Weighs 670 kg. Allows installation of a spit. Powered by wood and coal;

- "Fairy tale". Weight: 500 kg. Only charcoal should be used for cooking. With a height of 2.3 m, it has dimensions of 1.2 × 0.8 m.

Before you buy a brick barbecue, keep in mind that reviews of ready-made structures are not always positive.

More details on ForumHouse: https://www.forumhouse.ru/threads/199413/

How to choose a brick barbecue design: information relevant when developing a project

Among the many different barbecue options, the most popular are:

- barbecue stoves, made with a smoke collector above, through which smoke is removed from the grill;

- barbecue complexes with wide functionality;

- barbecue fireplaces.

Complexes are performed angular and frontal. They can have many elements, the need for which in each specific case is determined individually. Judging by the drawings and photographs, the dimensions of a front-type brick barbecue are usually 3.7 × 1.3 m, corner ones - 2.5 × 3 m. Good design may include not only a roasting pan, but also a smokehouse, an area intended for preparing food, various cabinets and much more.

Attention! Choosing a large complex will allow you to diversify the list of prepared dishes.

Frontal complex with wide functionality

Frontal complex with wide functionality Popular brick barbecue projects for DIY construction

If you decide to make a brick barbecue on your own, projects from already implemented solutions will come in very handy. We invite you to get acquainted with popular options that can be recreated on.

1 of 6

DIY construction of a brick barbecue oven

When starting to build a brick barbecue oven with your own hands, you need to prepare properly. You will need not only materials and tools, but also precise knowledge of the technology and drawings in accordance with which the work will be carried out. We suggest you figure out how to independently build such a building on your site.

What materials and tools are needed for work: an indicative list

When choosing materials for construction, you need to know which brick to use for a barbecue. You will need red and fireclay. The latter is intended for laying the firebox.

Attention! The required amount of brick depends on the design features and dimensions of the stove being built.

You will also need:

- furnace casting. The list, dimensions and quantity are determined at the drawing development stage;

- clay;

- for the device or the main components for its preparation;

- reinforcement to increase the strength characteristics of the foundation;

- Metal sheet;

- boards for ;

- waterproofing material;

- trowel;

- construction level;

- for wet cutting of bricks;

- with suitable circles;

- hammer with rubber striker;

- template for a semicircular arch.

How to prepare a drawing for a brick barbecue with your own hands: useful tips

When starting to develop a drawing of a brick barbecue with your own hands, consider the following points:

- area and strength characteristics of the foundation of the future structure. The foundation must be designed for future operational loads;

- design features and the height of the future furnace;

- design features of the roasting pan, skewers and grates;

- the presence of a canopy or gazebo. If they are available, it will be possible not to depend on weather conditions;

- Availability additional elements. In addition to the barbecue, you can provide a smokehouse or. They must be present in the drawing;

- wind protection system;

- coal storage area;

- design features.

A comment

Team leader of the repair and construction company "Dom Premium"

Ask a Question“When starting to develop a drawing of a brick barbecue with your own hands, download for free already ready-made solutions. They can be used as a basis."

Laying the foundation

The service life of a brick barbecue in a gazebo depends on the quality of the base. Work begins with preparing the pit. To do this, remove the fertile layer and remove the soil to a depth of 20-25 cm.

Attention! The dimensions of the foundation being laid depend on the size and design features of the barbecue. They should be 0.5 m larger than the size of the stove in all directions.

| Illustration | Description of action |

| A fifteen-centimeter layer of medium-fraction crushed stone is poured and compacted onto the leveled bottom of the pit. Pour a small layer of concrete. Let's do it. To do this, we drive the rods at equal distances, and also lay them lengthwise and crosswise, tying them at the intersection point. |

| We pour concrete to the level of the pit, cover it with a metal sheet on top and leave it for three days. The sheet should be laid on the bricks to prevent its contact with the poured mortar. |

| We set up the formwork and continue pouring the base. |

If you want to learn the sequence yourself, watch this video.

Preparation of clay solution

Dark red clay is selected for laying the stove. It is soaked for a day before preparing the solution and mixed thoroughly every other day. Sand is added to the soaked clay in a ratio of 1:2. To increase plasticity, glue for stoves and fireplaces is added to the composition (about 3% of the volume). The composition is thoroughly mixed. You can start laying.

Step-by-step brick barbecue laying

Arrangement of the firebox and chimney

Heat-resistant bricks are used for the firebox and chimney. The formation of the pipe usually starts from the 18th row. In each of them, a quarter of the brick is removed to narrow the hole. This is done until the 28th row. should be equipped with a valve.

Attention! Instead of brick, let's install a metal box.

We think you will find the following video with instructions interesting.

External finishing of the barbecue oven

Getting started external design, the finishing should be coordinated with the style of the house and other buildings located on the site. All elements of the complex should have a single decor.

How much does it cost to build a turnkey brick barbecue - price review

Not everyone can carry out the entire range of work on their own. But many are interested in the price of a turnkey brick barbecue. Here everything will depend on many factors, including the size of the building and its design features. If you decide to order a brick barbecue, pay attention to average cost popular models.

Meat, fish, and vegetables cooked with your own hands in a barbecue oven have an impressive taste and special aroma. It is not difficult to lay out the barbecue oven, observing necessary technology furnace work. We have prepared for you detailed instructions with drawings and order so that you can fold it yourself.

E. Gudkov's barbecue oven well combines two functions in one design - a barbecue grill and a hob with a burner.

Foundation

Materials

The main materials for a monolithic slab are: concrete, reinforcing mesh.

To construct the foundation, it is enough to use concrete with compressive strength B15 (M200). You can prepare it by following the following proportions:

- Cement M 400 - 1 part.

- Crushed stone or gravel, the size of which should be less than 30 mm - 4 parts.

- Sand - 2 parts.

Impurities in the sand of clay, organic particles, mica, and dust inclusions should be no more than 10% of its volume. In coarse aggregate (gravel, crushed stone), the amount of impurities that reduce the strength properties of concrete should be less than 2%.

Consumption of concrete components by weight per 1 m3:

- cement - 325 kg;

- sand - 1300 kg;

- crushed stone - 1300 kg;

- water 205 kg.

Armature

To reinforce the foundation, a mesh of class AIII reinforcement is taken

We accept the size of the foundation larger size oven 10 cm from each edge. If the furnace has a size of 1400x1000 mm, then the foundation will be 1600x1200 mm.

Tools

- probe (for compacting concrete);

- tamper (narrow), protected by metal;

- tamper (round) with two handles;

- rammer (square), covered with metal underneath;

- smoother (for leveling concrete);

- scraper (to remove laitance);

- grater;

- board (for smoothing concrete);

- trowel;

- shovel - straight cutting part;

- shovel - pointed lower part;

- shovel for mortar.

Laying concrete mixture

A properly selected and constructed foundation is a guarantee of the strength and durability of the entire structure. Here it is very important to know what kind of soil will become the basis for the stove. Sufficiently dense soil can easily support the structure of a barbecue oven. But there are pitfalls here that you need to be aware of.

There are soils that can change their volume due to wetting or lowering the temperature. These are swelling clay, subsiding loess and containing soluble salts, water-saturated (when ice freezes, the volume of soil increases), with particles of biological origin (peat), etc. These soils require special measures to strengthen them.

The marking of the future foundation can be done by pulling the twine over the pegs. The size of the pit for the sand cushion is taken according to the size foundation slab(160x120 cm). Since the barbecue oven will be located outside, the soil will winter period time will be subject to freezing and thawing. Depending on the type of soil, the depth of the sand cushion can reach 1000 mm.

Filling the hole with sand must be done in layers (15 cm) with compaction or pouring water to compact it. Before laying the sand, you can lay geotextiles on the ground, which allows water to pass through but prevents the sand from being washed away by groundwater.

Waterproofing consisting of 2 layers of roofing felt must be laid on the sand cushion. This will protect the concrete from water in the ground and keep uncured concrete from flowing into the sand.

Formwork boards are used from coniferous and hardwood with a thickness of at least 2 cm and no wider than 15 cm. The posts, to which the formwork boards will later be attached, are driven into the ground after 50 cm, and then reinforced with struts. Before you start installation concrete mixture, it is necessary to clean the formwork from dirt and moisten it.

Next, the reinforcement is installed in the formwork. The reinforcing mesh is tied into a three-dimensional frame using vertical rods, taking into account the distance between them and the size of the protective layer of the working reinforcement - 2 cm.

It is advisable to do concreting in one go. This will ensure the same curing time for concrete. Also, we must not forget about compacting the concrete mixture to remove formed air bubbles and compact the concrete.

To maintain the moisture regime necessary for normal hardening of concrete, it is covered with moistened burlap, tarpaulin or other similar material. You can, 3 hours after pouring the concrete, pour a layer of wet sawdust or sand onto its surface, which is periodically moistened (5 times a day). This regime is maintained for 7-14 days until the concrete reaches 50-70% of its strength.

Important! When the outside air temperature is below +5 °C, fresh concrete must be insulated to maintain a uniform setting regime.

The formwork can be removed when the concrete has gained at least 50% strength. In days it will depend on the air temperature:

- +5 °C - 12 days;

- +10 °C - 8 days;

- +15 °C – 7 days;

- +20 °C - 6 days.

In any case, the indicator for the possibility of removing the formwork will be the hardness of the corners and surface of the structure. It is possible to begin work on the construction of a barbecue oven only after 2 weeks, taking into account the air temperature.

Gudkov barbecue oven body

Materials

- Fireproof brick (fireclay) GOST 390-96.

- Ordinary clay brick GOST 530-2012.

The furnace body is made of either refractory or ceramic brick (necessarily solid). Fire brick withstands temperatures of 1300 °C and more. Ordinary clay brick must be well fired. Unburned, hollow, silicate, and cracked bricks are not suitable for stove masonry.

The stove will require 465 bricks.

Furnace appliances:

- single-burner hob 420x500 mm;

- barbecue grill 420x500 mm;

- a metal sheet 500x600 mm;

- cleaning door 140x140 mm;

- blower door 270x140 mm;

- combustion door 250x270 mm;

- grate 300x200 mm;

- steel corner 32x32x4 mm, length 500 mm - 4 pieces, 600 mm - 6 pieces;

- steel wire 2 mm - 10 m;

- asbestos cord 5 mm - 10 m.

Clay-sand solution

For furnace work, mainly plastic, most often red clay and fine sifted sand are used. Required proportion The composition of the solution is taken based on the fat content of the clay. The fat content depends on the percentage composition of sand in it:

- oily - 2-4%;

- average - 15%;

- skinny - 30%.

Composition of the solution (clay, sand):

- oily - 1:2.5;

- average - 1:1.5;

- skinny - 1:1.

Important! Before starting work, the clay is soaked for a day, and then, gradually stirring, sand is added little by little.

You can also buy ready-made mortar mixture for furnace work. Such mixtures can withstand high temperatures and will significantly reduce the time required to prepare the solution.

Stovemaker's tool

Stove masonry is the same brickwork, so basically the tool for it is almost the same.

1 - pickaxe; 2 - trowels; 3 - mallet; 4 — jointing; 5 - plumb line; 6 — level; 7 - square

1 - pickaxe; 2 - trowels; 3 - mallet; 4 — jointing; 5 - plumb line; 6 — level; 7 - square

Garden combi stove body

Work on the construction of the furnace body must be carried out only if there is at least a temporary canopy over it. For ease of work, you can first lay out the body dry, selecting bricks.

Important! The chipped side of the brick cannot be placed inside the firebox or chimney.

Before laying, clay bricks are moistened for 1-2 minutes. dropping into the water. Fireclay brick Just rinse to remove dust. The seam thickness for clay bricks should be less than 5 mm, and for fireclay bricks - 3 mm.

When performing furnace work, it is necessary to maintain strict horizontality of the surfaces of each row and verticality of the corners. The dressing of the seams should be 1/2 brick.

All furnace appliances are installed simultaneously with masonry work. Metal and brick have different sizes linear expansion, so that's it metal elements stoves are installed with a gap of 3-5 mm, then this gap is filled with asbestos cord.

Steel wire is attached to the stove doors to embed it into the masonry.

Orders

You can install a cast-iron cooking stove, or you can install a barbecue grill if desired.

When installing a vault over hob the brick is installed on steel corners. A barbecue grill or cast iron stove is also placed on the corners. Chimney channel for garden barbecue oven you can make 270x140 mm, 270x270 mm, and also 400x140 mm. The inner wall of the chimney must be plastered so that it is smooth and does not allow soot to accumulate in uneven areas.

For fire safety The barbecue oven is installed no closer than 7 m from the walls of the house. The finishing of such a stove is chosen according to the owner’s taste. This can be jointing, plastering or tiling.

Drying the oven is done carefully, without rushing. It is heated with a small amount of fuel for 3-8 days.

Any holiday on fresh air One can hardly do without deliciously cooked food on the fire, which saturates it with the energy of nature. And a home-made oven will embody any recipes of a hospitable host.

Most often, holidays outside the city are associated with preparing delicious dishes of meat, fish or vegetables. The beauty this lesson is cooking over coals.

Of course, you can purchase a ready-made device for creating dishes, but creating such a device yourself will save you effort and money. How to make a barbecue for your dacha with your own hands, see later in this article.

Origins of barbecue

The word "barbecue" is translated as "barbaric". It refers to a barbarian (foreigner) who cooks food over a fire in the open air. The townspeople thought it was unusual for travelers with this method of cooking, but later cooking over coals won the hearts of many people. However, what is the difference between a barbecue and a classic barbecue? Let's look at this question in more detail.

It is a special container for coals, top edges which serves as a container for skewers with food.

Barbecue, in turn, involves placing the product at a depth under the side of about 20 cm. At first glance, this difference seems insignificant, but from a culinary point of view the difference is huge: while the product cooked on the grill is not exposed to smoke, a product made on a barbecue contains the slightest smoke.

We must not forget about the role of the side in the grill: since the sides create a volume of hot air, the meat turns out more juicy and rosy, while the grill “dries out” the dish. Therefore, from a culinary standpoint, barbecue can give you rosy and juicy dishes, soaked in a pleasant smoke.

DIY BBQ oven

In order to successfully build this stove, first decide on a sketch of the mechanism. It is necessary to take into account such elements as the roof, sink, woodpile, firebox and countertop. After you have depicted the future stove, decide on its location in the interior. After this stage, prepare everything you need:

- Set of fasteners;

- BBQ grill;

- Tray under coals;

- Brick;

- Sand and clay;

- Ruberoid;

- Crushed stone and cement.

Here is an algorithm for creating a brick barbecue oven:

- Start preparing the foundation. To do this, you need to dig a pit below the normal freezing point. Pour 6-8 cm of sand into the bottom of the pit and compact it. Place reinforcing bars at the bottom of the pit and fill its contents with concrete.

- After about 25 days, when the concrete has hardened, you can proceed to the next step. Use roofing felt or thick polyethylene film to create waterproofing.

- Laying bricks won't take you any time large quantity energy and time. To do this, read the special instructions on the Internet and choose the one you like. Please note that the brick in the area of the firebox and stove must be laid on a clay mortar.

- After erecting the stove itself, it is necessary to light the wood or corner in the stove and bring the mass to the maximum temperature. This is necessary for firing interior walls designs.

- Now you need to dry the oven. IN summer days the procedure will take about five days, but in the fall it will take at least twenty days. Don't forget to protect the oven from moisture: cover it with protective film.

Easy BBQ Fryer in Ten Minutes

The simplest way to create a brazier, which does not require any construction skills or even mortar for laying bricks. To create it, you will need about a hundred bricks (although the amount of material depends on the height of the future structure), a sheet of metal and a lattice.

The size of the last two should be approximately equal, and their width determines the width of the entire structure.

Lay the bricks directly on the dry, so that the resulting brick stands firmly, and the laying method will resemble a child's game of blocks. Between two layers of bricks you need to place a sheet and a lattice.

Ready! You can enjoy cooking without special effort and costs.

Gazebo with barbecue

For a barbecue, prepare brick or stone, as these materials not only have excellent fire safety parameters, but also look simply lovely.

Metal structural elements are also important: you should give preference to cast iron, since this material is resistant to high temperatures and safe. As an alternative to cast iron, you can choose stainless steel, however, in terms of its characteristics it is inferior to cast iron. Fireproof tiles will become good material for the floor.

In order to build this design, start preparing the foundation as described above. So, sandy base should be located above the ground, on top of it - concrete with reinforcement, and above them there should be a waterproofing system.

Next, start laying bricks. To do this, you will need a solution with clay and sand mixed 1:3. Next, add water to the mixture until the consistency of the solution becomes similar to sour cream. Next, fold the oven into a “P” shape, the height of which should reach approximately 1 meter.

Place two cast iron grates at a distance of 25 cm from each other. The first grate will serve as a container for food, and the second one will be used to light the fire.

A barbecue is one of the best items to have in your garden, as it encourages you to enjoy spending time in nature and prepare the most wonderful dishes.

Of course, you can purchase ready-made barbecue devices, but creating a structure with your own hands will instill in you pride in your own work and joy in the hearts of your household.

Drawings and diagrams of a homemade barbecue

Photo selection of homemade barbecues for the garden

These tips will help you create beautiful dishes on a structure made by yourself.

Ask your question