Bitumen roof. Soft roofing (single-layer, double-layer, multi-layer flexible tiles). Bitumen mastic as a material for roof repair

Price list Price list |

manufactured by the Russian enterprise "RBP". Product quality meets the highest international standards. Soft roof Ruflex offers excellent performance characteristics and a wide range of shingles. The tiles are made from high-quality bitumen, which contributes to their special elasticity and resistance to climatic factors. |

| The famous Italian brand is well known in many countries of Europe, Asia and North America. For several decades, the company has specialized in the production of flexible tiles. The product range includes about 50 different shingle options and more than 100 color solutions. Tegola soft roofing, which you can buy at Stroymet offices at low prices, occupies a leading position in the European market - almost 50% of the total output (over 10 million sq. m are produced annually). The raw materials for the products are two types of bitumen, as well as basalt granulate and fiberglass. Unique composition ensures maximum resistance of products to external factors. | |

Price list Price list |

Double-layer tiles for the price of a single-layer! Soft roofing is manufactured on automated production lines equipped with high-quality foreign equipment. The trademark belongs to domestic company TECHNONICOL and the Spanish corporation CHOVA. The products comply with Russian and European quality and safety standards. Flexible bitumen shingles Shinglas perform well in the Russian climate at any time of the year (they are not afraid of cold, rain, strong wind, heat). Multilayer flexible tiles based on bitumen retain their original characteristics for decades. |

Price list Price list |

Finnish bitumen shingles have been known on the building materials market for more than 60 years. During this period, the products have gained wide recognition in Scandinavian countries, Eastern and Western Europe, as well as Asia. The Katepal company produces soft roofing only in Finland. Modern equipment, qualified personnel, strict technological control allow us to maintain the highest level of quality of our roofing materials, which are exported to dozens of countries, including Russia. Soft roofing Katepal is made of fiberglass coated with SBS-modified bitumen polymer. The company guarantee is provided for a period of up to 25 years. The actual service life of tiles is more than 50 years. |

Price list Price list |

is manufactured by Deke Home Systems in Russia under the control and methodological guidance of experienced German specialists. The enterprises are equipped with the best foreign equipment, which allows them to produce products of excellent quality. In addition to roofing coverings in the offices of the Stroymet company you can buy favorable prices and other Docke products - vinyl siding, façade panels, drainage systems, lining carpets, membranes, mastics and much more. |

Price list Price list |

Soft roofing is produced by Diversified production company"KRZ". The Russian brand uses great success in the building materials market, thanks to the good quality-price ratio. Modern equipment and strict compliance control technological processes at all stages of production allow us to produce strong and durable roofing material. |

|

American flexible tiles CertainTeed have a huge assortment and variety of exclusive shades. The company was founded more than 100 years ago and is currently a world leader in the production of soft roofing. Our country presents products of various price categories, ranging from the most affordable to the exclusive. |

|

Produced at French and Finnish enterprises. Modern equipment and high-quality raw materials allow the company to produce products of impeccable quality. Russian consumers became acquainted with the brand's products more than 10 years ago and appreciated Ikopal's soft roofing. Collections of flexible tiles are especially in demand in residential and commercial suburban construction. |

Price list Price list |

The soft roof is manufactured by the famous Finnish company Lemminkainen. European raw materials and special production technology provide increased strength roofing covering. Inner side shingles are covered with dense polymer film. Thanks to this, the level of tightness of the roofing pie is significantly increased. The service life of flexible bitumen shingles of the Kerabit (Pikipoika) brand exceeds 40 years. |

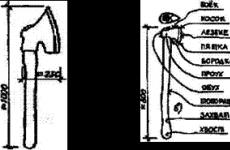

Flexible tiles are one of the most popular modern roofing coverings. Soft roofing, bitumen shingles, shingles, as well as shingles or roofing tiles are all names for the same material. The standard sheet size is 100 by 33 cm. One of the edges usually has figured cutouts. The most popular shapes of shingles are square, diamond, rounded, rectangular and hexagonal. At the offices of the Stroymet company you can buy bitumen shingles from leading Western and Russian brands:,. We offer modern roofing materials at competitive prices!

Flexible tiles are one of the most popular modern roofing coverings. Soft roofing, bitumen shingles, shingles, as well as shingles or roofing tiles are all names for the same material. The standard sheet size is 100 by 33 cm. One of the edges usually has figured cutouts. The most popular shapes of shingles are square, diamond, rounded, rectangular and hexagonal. At the offices of the Stroymet company you can buy bitumen shingles from leading Western and Russian brands:,. We offer modern roofing materials at competitive prices!

Soft roof structure

The standard base for shingles is fiberglass. In some cases, it is made from cellulose. One more mandatory element is bitumen (natural or modified). Thanks to the addition of polymer components, shingles acquire additional strength and elasticity. The outer layer of the soft roof is basalt granulate. It performs several important functions: forms the color of the coating and also protects the tiles from damage, weather influences and ultraviolet radiation. The inner layer is usually a polymer self-adhesive film or quartz sand.

| Self-adhesive soft roofing hexagonal shape | |

|

|

| Standard rectangular soft roof | |

|

|

Application of soft roofing

Application of soft roofing

The main requirement for the roof structure is that the angle of inclination of the slopes must be at least 12°. Its configuration can be any. Soft tiles are suitable for use both in buildings under construction and in renovations. It is not necessary to dismantle the old roofing covering (if any), you just need to properly prepare its surface for the installation of bituminous shingles. It is usually used in private suburban construction, in the construction of high-rise residential complexes, industrial, commercial and social facilities. It is very simple to buy flexible bitumen shingles at low prices from the Stroymet company - just call us, and qualified managers will help you.

Advantages of a soft roof:

- Resistance to seasonal and daily temperature changes (can withstand severe frosts and heat).

- Attractive appearance.

- Durability.

- Does not fade in the sun.

- Light weight (no need for significant reinforcement of rafter structures and foundation).

- Not susceptible to corrosive, chemical and biological effects (rodents, insects, mold, lichens).

- Convenient transportation and simple installation (no special equipment and ideal slope geometry required; minimum waste).

- Excellent sound insulation (including during rain, hail, strong wind).

- Tightness.

- No need for special care and additional processing during operation.

- The relief surface allows you to do without the mandatory installation of snow retainers that prevent avalanche-like snow from falling off the slopes.

- Simple repair (if damaged, just replace individual shingles).

Roofing pie structure

Base for soft roof

According to Stroymet engineers, best base for installation of flexible tiles - a continuous sheathing made of moisture-resistant plywood, dry tongue-and-groove boards (pine, spruce, larch).

Rules for storing bitumen shingles

- The optimal container is Euro pallets 1 by 1.2 m.

- It is prohibited to stack pallets on top of each other.

- The maximum number of soft roofing packages on a pallet is no more than 30-50.

- The material must be protected from exposure to solar ultraviolet radiation to avoid caking.

|  |

The excellent performance characteristics of flexible tiles make them especially in demand on the Russian market. At Stroymet offices you can buy soft roofing from leading Russian and foreign brands at a low price. We offer a wide range of products from the brands Tegola, Deke, Ruflex, Katepal, Shinglas, Kerabit and many others.

Soft roofing is one of the popular types roof coverings. It is successfully used both in the construction of private houses, outbuildings, and for multi-storey buildings. Materials of this group are made on the basis of bitumen and fiberglass. They have such advantages as: ease of installation, increased noise, hydro and thermal insulation properties. Moreover, even for repairs special costs not required. And you can do all the work yourself.

Roof repair documentation

When conducting repair work on a soft roof are guided by the following documents:

- estimate (work performance document). It takes into account all planned repairs on a given roof. For example, dismantling the roof, preparing the base, installing new material and sealing seams, creating a waterproofing layer. The estimate includes the cost of consumables and combustible materials, as well as the cost of their delivery. This document will help you estimate the budget for future repairs and decide whether to carry it out yourself or to allow specialists to do it;

- SNiP (building codes and regulations). During repairs, it is important to follow the requirements set out in the SNiP document “Repair of Soft Roofing” number 11-26-76. It lists everything necessary materials for waterproofing, types of mastic, roofing materials and requirements for the order of work;

- PPR (works project). This document is important if roof repairs are being carried out apartment building. It indicates the rationale for the repair work, the results of the roof inspection, its characteristics, methods of organization and production methods roofing works.

Types of damage and types of repairs

Soft roofing requires periodic inspection. It will help to identify any violations of the integrity of the roofing covering in a timely manner and carry out restoration work in a timely manner. Common problems with soft roofs are:

Swelling of a soft roof may occur as a result of violation of the technology for laying materials

Moss on a soft roof appears as a result of improper installation technology

Delamination of the roofing material can be repaired by sealing the ends and strengthening the seam with a patch

Soft roofing may crumble after the end of its service life or under unfavorable conditions of use.

Bituminous shingles Over time it may change color and even delaminate.

A preventive examination should be carried out at least twice a year. It is recommended to regularly clean the roof of branches, debris and snow. These measures will increase the service life and minimize repair costs.

Depending on the type of damage, there are three types of soft roof repair work:

- Local or current - implies elimination small defects roofing sheet.

Local repair of fused roofing ensures quick restoration of the coating at low cost

Overhaul of the roof consists of removing the old covering and laying new material

Emergency repairs are carried out immediately after an unexpected violation of the roofing covering to avoid even bigger problems.

Soft roof bitumen

Soft roofing is found everywhere today. It is convenient to install, so its popularity is only growing from year to year. Soft roofing materials can be produced either individually or in rolls, made from various materials. Another undeniable convenience is that repairs, elimination of defects and the waterproofing process do not require large investments and time. However, first things first.

Features of a soft roof

This type of material is one of the five most popular in Russia. They cover bathhouses, cottages, garages and gazebos. Soft roofing is made on the basis of:

It is bitumen that makes it possible to easily solve problems in the form of defects, swelling, the appearance of fungus and other troubles. From time to time it is necessary to check the roof for its integrity and make repairs. We will tell you how to do this in our article.

In addition, the soft roof looks very attractive. Its light weight is also a plus. There is no additional pressure on the roof base, structure or foundation.

Possible problems during operation

To extend the life of a soft roof, it is necessary to inspect it twice a year for defects, the causes of which can be many. You need to pay attention to:

- peeling at joints;

- bloating;

- the appearance of cracks and other damage where water could accumulate.

Correcting problems in a timely manner will keep the coating in its original form and extend its service life. High-quality repairs are the key to excellent roof waterproofing.

Repair of soft roofs is carried out using bitumen mastic. You can purchase it or make it yourself. In addition to repairs, bitumen can also be used:

- for roof waterproofing;

- for sealing seams;

- for carrying out anti-corrosion measures on a metal roof;

- for the production of soft roofing.

However, let's talk about repairs in more detail. The fact is that today the market is overflowing with various sealants and mixtures for repairing soft roofs. Anyone can get confused in this diversity. Let's say a defect is discovered that requires repair. What should someone who decides to immediately make repairs do? First of all, you need to choose the material.

Bitumen mastic as a material for roof repair

We suggest considering simple bitumen mastic as a material. Its advantages are as follows:

- it is an economical product;

- the material has been tested for generations;

- repairs are carried out quickly and efficiently.

Characteristics of the material and its advantages

Modified bitumen is a solution of two or more components. Let's look at the positive characteristics:

- increased elasticity and viscosity;

- resistance to oxidizing agents, alkalis and other aggressive materials;

- withstands elevated temperatures up to +100 degrees;

- not afraid of sunlight;

- withstands low temperatures down to -40 degrees;

- easy to apply and light weight;

- has high strength;

- there will be no seams after application;

- meets all waterproofing requirements.

Thus, the material can be used on any type of roof: single-pitched, multi-pitched, flat, and so on.

Physical properties, especially increased elasticity, allow the hot solution to stretch, as needed by the master, and after hardening to shrink. There will be no unpleasant consequences from this. The consumption of mastic per 1 m2 is extremely small. It is believed that this is the most best quality solution. The problem with many materials that try to replace bitumen mastic is that when applied to a crack, they can break over time. The crack itself, under the influence of temperature, humidity and sun, even with mastic, will try to expand. Bad material Over time, it simply won’t withstand this stretching.

All mastic for repairing soft roofs can be divided into two types according to the method of its application:

- cold application;

- hot application.

In addition, today a huge amount of roof repair material is produced in the form of bitumen mastic with different compositions.

In addition to bitumen, the composition may include:

- rubber;

- isobutylene;

- polymer modifier;

- other additives.

In appearance, mastic is a black homogeneous mixture in the form of briquettes, paste, liquid or thick glue. Depending on the form in which it is produced, the method of its use and the material consumption per 1 m 2 change.

Manufacturers, in turn, also divide all mastic into four types:

- Polymer cold application (used for almost all types of repairs, including anti-corrosion treatment).

- Roofing (used for waterproofing, but the name itself comes from the method of use when applying rolled roofing material to the roof).

- Rubber for cold use (for repair work and sealing joints).

- Adhesive (functions similar to those of roofing mastic).

Compositions various manufacturers differ, however, the main component remains unchanged long years. This is modified bitumen of petroleum origin. For increased elasticity, latex and synthetic-based resins are used. The resulting ductility affects the material consumption.

Additionally, one cannot help but mention the disadvantages of bitumen:

- liquid bitumen can leak, so many manufacturers add various modifiers to its composition;

- in severe frost (below 40 degrees), the material may crack.

To prevent the formation of cracks, special compounds supplemented with additives are used for roofing work in the north of the country. This should be indicated on the label.

Selection of mastic for repair work

When making your choice, carefully study the label. Good material must be manufactured in accordance with GOST 30693-2000 or GOST 14791-79. Regardless of whether the bitumen in front of you is modified or not, you need to check a number of parameters:

- density should be in the range of 1000-1100 kg/m3;

- the expiration date must be indicated on the packaging;

- the seller must provide a quality passport and a certificate of conformity;

- The drying time is indicated provided that the window outside is +25 degrees (standard is 24 hours, but if this time is less, it means that very little solvent has been added to the modified bitumen, which is not very good).

Consumption per 1m2 is also important for savings. Another question that worries buyers is whether to buy cold or hot mastic? Let's understand the difference between them.

Cold mastic is ready for use. The manufacturer may insist that it needs to be heated slightly, but the maximum temperature will be 40 degrees. It is good because it reduces the time of repair work and is not afraid of moisture. If it has recently rained and the roof has not yet dried completely, you can pour cold mastic to eliminate leaks, waterproof, and repair soft tiles.

The hot-applied material is very good, but requires compliance with safety regulations. The temperature reaches 150-200 degrees.

In addition to purchasing ready-made material, you can make liquid hot bitumen yourself.

Self-cooking

To prepare the solution you will need:

- old metal bucket;

- materials for lighting and maintaining a fire;

- bricks;

- bitumen;

- gasoline (if necessary);

- a strong wooden stick for stirring.

First you need to make a fire. Now, hang a bucket over it and put bitumen in it. The material will slowly melt when exposed to high temperatures. The mixture needs to be stirred from time to time.

If the mastic turns out to be very thick, gasoline is added to it. The consumption of the final product will be small.

Process self-made and application is shown in the video.

Repair work

Depending on what a visual inspection of the soft roof shows, repairs are divided into:

- emergency (waterproofing process in the presence of leaks);

- small (sealing cracks and seams);

- capital.

For minor repairs, small pieces of roofing felt, soft tiles or other material are needed. First, the crack is filled with a liquid solution, then a piece of roofing material is glued, everything is compressed and a new layer of bitumen is applied on top. For such work, the material consumption per 1 m2 is minimal.

Emergency repairs require high-quality waterproofing. In case of leaks, it is necessary to apply mastic under the roofing material, first drying the area with a burner. The same method is used when the seams of a soft roof diverge. The consumption in this case is also small.

Major repairs are the most difficult of all; bitumen consumption here needs to be increased. The process itself can be divided into three stages:

- the damaged sheet is removed from the roof;

- prepare modified bitumen according to the instructions;

- a layer of waterproofing (special material) is lined;

- Using a solution, the roof is again covered with roofing material.

In cases where water is retained on the roof, it is filled with water without a sheet and this area is marked. After this, the liquid is distilled off, the surface is dried and modified bitumen is applied, followed by roofing material 1 millimeter thick. Now you can cover the roofing material.

Bitumen mastic- excellent material. Low consumption, efficiency, ease of use and high quality waterproofing have provided it with an impeccable reputation.

Cold-applied bitumen mastic for waterproofing and gluing roofing felt: consumption and technical characteristics + Photo

This article will help you understand what cold-applied bitumen mastic is. What is the difference between cold and hot mastic. Where is it used? How to choose the right material based on properties and qualities for the required work.

This article will help you understand what cold-applied bitumen mastic is. What is the difference between cold and hot mastic. Where is it used? How to choose the right material based on properties and qualities for the required work.

Bitumen is a hard resin, and mastic is made from it. In order for the material to become plastic, its temperature is increased, which significantly increases the work time and has an obvious drawback - the risk of fire.

For this reason, it is much more convenient to use cold applied mastic. Thanks to the solvents present in the composition, the waterproofing material is in a liquid state and does not require heating for use.

Hot and cold mastics are used to achieve complete waterproofing. The solvent evaporates and the material hardens. The result is a high-strength waterproofing layer.

General information about bitumen mastic

There are two types of cold applied bitumen mastic

First view

Manufactured using solvents. These are completely ready-to-use mixtures. Solvent-based mastic is suitable for use at sub-zero temperatures.

This type of waterproofing sets within 24 hours. It takes a week for the mastic to completely harden and acquire waterproofing properties.

Typically this type of material is used in roofing work.

The second type of bitumen waterproofing coating

Manufactured at water based– what characterizes the material if not harmful ecology.

The coating does not have a strong odor and dries in a couple of hours.

Water-based waterproofing cannot be used at low temperatures. The material should also be stored in a warm room.

Bitumen mastic has different modifications

Unmodified waterproofing. The composition does not contain polymers or other components that increase the properties of the material. This type is not suitable for roofs, but for foundations perfect option. The waterproofing used for the foundation does not experience atmospheric overloads.

It is not recommended to use mastic without polymers for roofing work.

Bitumen- polymer mastic . From the name of the material it is clear that this type of waterproofing has high performance. Perfectly adapted to a wide temperature range. Very good molecular bond (adhesion), which allows the mastic to be used for gluing roofing felt and similar materials.

Due to its properties, bitumen-polymer mastic is widely used for covering flat roofs.

Bitumen-rubber mastic. The composition contains rubber crumbs. It has decent anti-corrosion properties. Used for coating metal structures.

Bitumen-rubber mastic is NOT suitable for roofing work.

Bitumen-rubber waterproofing, she's the same liquid rubber- very elastic with high physical and mechanical properties. These qualities increase the wear resistance of the coating. Perfect for roof covering.

Rubber mastic can become an independent roofing covering. Practically not subject to atmospheric influence.

The type of mastic is directly related to the components it contains.

One-component – ready-to-use coating.

Two-component mastic requires mixing with a hardener before starting work. Used for professional purposes. Has good performance.

When using a two-part mastic, it is IMPORTANT to follow the mixing instructions exactly. Incorrect proportions will lead to an increase in hardening time.

The main advantages of cold-applied bitumen mastic

- Reduces waterproofing work time

- The mastic can be diluted with a solvent, which will make it the desired consistency

- Service life more than 25 years

- The coating can be used on surfaces made of different materials

- Easy to apply.

- Independent use

Disadvantages of this material

- High price.

- Bitumen-polymer mastic gives greater shrinkage, which affects material consumption.

Application

Cold application bitumen mastic material consumption:

- For gluing 0.8 – 1 kg per square meter

- For a waterproofing layer 2 – 3.8 kg per square meter

There are two leading manufacturers on the market:

- Bitumen mastic TECHNONICOL

- Bitumen mastic EXPERT

Both manufacturers meet all requirements. There may be differences in prices. And some nuances, such as material consumption and drying time.

Important to remember. Before using mastic, it is necessary to clean the surface of debris and dirt. The area to be treated must be dry. If the surface is porous, it must be pre-treated with a primer.

Bitumen mastic for roof

In construction, bitumen-based building materials are now often used. In particular, bitumen roofing, bitumen tape for roofing, as well as various polymer-bitumen based sealants.

Bitumen mastic for roofing is widely used - it is made on the basis of bitumen, it allows you to simply and efficiently carry out waterproofing and roof repairs. Roofing mastics are well resistant to aggressive environments. One of their main advantages is that they can stretch and shrink without any consequences, are applied evenly to the roof of any configuration, and the work is performed seamlessly. Thanks to these properties, the coating is reliable and durable.

Bitumen mastics used for roofing work are of the following types.

Cold application

bitumen mastic expert

Cold bitumen mastic is a ready-to-use composition, although it can be diluted if necessary various solutions. It can be applied even to a wet coating, which allows you to carry out work without special preparation and in the shortest possible time.

Hot application

Water based

They are the most environmentally friendly, because the content of toxic substances in them is minimal. They are easy to use and safe.

Bitumen mastics with special additives and fillers (plasticizers, minerals, etc.) have any specific properties:

Rubber mastic and polyurethane are the most elastic; they contain rubber or polyurethane.

- Bitumen-latex - very durable with increased water resistance, contain synthetic binders and mineral fillers (latex, asbestos, mineral wool fibers, modifiers).

- With an oil solvent - it does not harden, it is usually used on objects with constant vibration.

- Rubber-bitumen - resistant to stretching, shock and vibration, easily adheres to any surface.

rubber-bitumen mastic for cold application

Rubber-bitumen mastic is most often used for cars, but it is also successfully used for repairing roofs.

Now let's look at the application various types bitumen mastics for roof repairs.

Soft roof repair

Repair with a patch. Bituminous roof mastic is usually applied manually using a spatula or brush, sometimes with a spray. The surface of the roof to be repaired is cleared of dirt (rust or old paint does not need to be cleaned) and covered with mastic, then a patch is applied. For the patch, you can use bitumen tape, tarpaulin, etc. The patch must be pressed tightly to the surface so that there is no air gap left. You can apply more on top protective layer from mastic.

Roof repair using bitumen mastic and roofing tape. Bituminous roofing tape is usually used to repair soft roll roofing. This tape is multi-layered - it has a protective layer of aluminum foil, a layer of bitumen with plasticizers and a layer of polyethylene film. It adheres well to various materials. Good quality tapes do not contain harmful chemical additives, are tear and puncture resistant, and their protective reinforced surface is resistant to contamination, acids, alkalis and other aggressive environments. These tapes are very easy to use and do not require special skills to use. Let us examine in detail the repair method using bitumen tape.

bitumen mastic for repairing soft roofs

First you need to clean the leak area and the area around it from dirt, rinse thoroughly with water or a cleaning solution, and let it dry completely. Lubricate the leakage contour with bitumen mastic or primer. Next: remove the protective film from the adhesive side of the tape. Then, using a pressure roller, fix the tape on the roof surface and cut it along the edge.

Repair using flashing method. The roof surface is cleaned, treated with a primer, degreased if necessary, cracks are sealed with moisture-resistant putty. cement based. Next, two layers of mastic are applied, then reinforced geotextiles are laid and a protective layer of mastic is placed on top.

Hard roof repair

Repair of corroded areas. Hot mastic is usually used to repair hard roofs. First you need to remove the rust, clean the surface of dirt, then apply a layer of hot bitumen mastic.

Repair with a patch. First, we prepare a patch of the required size from a dense material (tarpaulin, burlap), then we impregnate it with a mastic composition and fix it on the place to be repaired, leaving it to dry well. Then apply another layer of mastic on top. This method is good for sealing interlocking surfaces.

Approximate consumption of bitumen mastic per 1 m

The consumption of mastic depends on its type and is often indicated in the description of the composition.

Hot applied mastics do not shrink much. To apply bitumen mastic in a layer about 2 mm thick, approximately 2.2 kg/m2 of composition will be required.

Typically, ready-to-use mastics shrink, and to create a 2 mm layer you need about 3.6 kg/m2 of composition.

bitumen mastic consumption per square meter

If necessary, to reduce consumption, the composition can be diluted slightly. So how to dilute bitumen mastic? You can dilute bitumen mastic with white spirit, solvent, toluene, kerosene, etc. For safe dilution, you need to carefully read the manufacturer’s instructions for working with the composition.

Bitumen sealants for roofing

In some, especially problem or hard-to-reach areas of the roof, it is better to use specialized sealants to better achieve the waterproofing effect. Bitumen sealant for roofing - this is a special viscous composition made from modified bitumen. It is quite toxic and is used only for outdoor use. It is well resistant to moisture, ultraviolet radiation, various oils, solvents, and gasoline. Bituminous sealant is applied at temperatures above freezing, usually in several layers. For roof repairs on small surfaces, rubber-bitumen sealant is well suited, since it is vapor- and waterproof and very elastic.

Thus, to summarize, we can say that bitumen is widely used for roofing work, since it has very good performance and consumer properties. Bituminous materials the right type, you can easily buy it in a store or make it yourself. You don't need complex ones to use them. preparatory activities, special tools or extensive experience. However, when carrying out repair work, you should still pay some attention to their choice. Sometimes different types of roofing may have their own specific characteristics. If you find it difficult to choose materials for repairing your roof, then it is better to use only universal, high-quality products. New materials allow roof repairs to be carried out quickly and efficiently.

From this video you can learn more about roof repairs with cold-applied bitumen mastic:

Cold application bitumen mastic - the main points you didn’t know about

What is cold bitumen mastic? How does it differ from hot, and for what purposes can it be used? I'll tell you about the main properties of this insulating material and the scope of its application. This will allow you to choose the most suitable one for yourself. suitable option waterproofing.

Cold application bitumen mastic is a universal modern waterproofing material

What is the material

General information

Bitumen mastic is a plastic material made on the basis of bitumen. The latter is a solid resin. Therefore, the bitumen-based mixture is heated before use.

Hot applied mastics are not very convenient to use. The need for warming up increases the time spent waterproofing works, and also increases the fire danger.

Therefore, cold-applied analogs have become more popular lately. They contain solvents, as a result of which they are sold in liquid form and do not require heating.

In the photo, cold applied mastic is a liquid waterproofing material ready for application.

The principle of action of such compositions is similar paint and varnish materials- after application to the surface, the solvent evaporates and the coating hardens. As a result, a durable waterproofing layer is formed.

Compound. Cold applied bitumen mastics, depending on the composition, are divided into two types:

- Solvent based. Ready-to-use mixtures that can be worked with even at sub-zero temperatures.

The coating dries a day after application. True, the material acquires its final properties only a week after application.

Typically, solvents are used in the manufacture of roofing mastic, but this waterproofing material can be used for other purposes. More details about possible options I will describe the uses below;

Water-based bitumen emulsion mixture is environmentally friendly

- Water based. This cold applied mastic is an aqueous emulsion. Thanks to this, it is odorless and environmentally friendly.

Besides, water-based coating dries faster - it usually takes several hours. True, it can only be used at above-zero temperatures, the same applies to storing the material.

Modifications. Depending on the initial components that are used in the composition, the material in question is divided into the following types:

- Not modified. These coatings do not contain polymers or other improving additives. Therefore, they are not recommended for use for roofing, but at the same time they are excellent for waterproofing foundations, where they are not exposed to strong temperature changes and heating;

The unmodified composition can be used for foundation waterproofing

- Bitumen-polymer. Bitumen roofing mastic is usually modified with polymers. It tolerates heat and temperature changes well.

Another positive quality is increased adhesion. Thanks to this, the composition can be used for gluing rolled materials;

The bitumen-polymer coating is not afraid of high temperatures, which allows it to be used for waterproofing flat roofs

- Bitumen-rubber. They differ from each other by adding crumb rubber to the composition. Typically used for waterproofing metal building structures, as they have good anti-corrosion properties. This waterproofing material is not used for roofs;

- Bitumen-rubber. This coating is characterized by increased elasticity, as well as excellent physical and mechanical properties, which is why it is also called liquid rubber. Such compositions are excellent for roof repairs.

Moreover, thanks to high efficiency, durability and weather resistance, they can be used as an independent roofing covering.

Before applying a waterproofing coating, regardless of its type, the surface must be carefully prepared - cleaned of foreign debris, dust and dirt, and then thoroughly dried. In addition, it is advisable to pre-apply a bitumen primer.

Depending on the number of components, bitumen coatings are divided into two types:

- One-component. They are a completely ready-to-use coating;

- Two-component. Must be mixed with hardener before use. These compositions are professional and have higher characteristics.

When mixing two components, it is extremely important to maintain the correct proportions, otherwise the drying time of the coating may increase dramatically. Instructions for mixing the components are available on the packaging.

Basic qualities

As I said above, unlike hot bitumen mastic, the analogue for cold application is convenient to use and speeds up waterproofing work. But besides this, it has many other advantages:

- Possibility of obtaining any consistency. To do this, add to the composition required amount solvent;

- Durability. This quality applies primarily to modified compounds whose service life exceeds a quarter of a century;

Modified bitumen mixture can last on the roof for more than 25 years

- Versatility. Mastic can be used to waterproof a wide variety of surfaces;

- Easy to apply. The coating is easily applied with your own hands using a roller, spatula or brush.

Flaws. The only downside is the higher cost; bitumen-polymer mastic is especially expensive. In addition, this waterproofing shrinks more strongly than its hot-applied counterpart, which increases its consumption.

Mastic consumption depends on the type of work. Bonding usually requires 0.8 to 1 kg/m2 of coating per square meter. To create a waterproofing layer per square meter it takes 2 to 5 kg of composition.

%D0%96%D0%B8%D0%B4%D0%BA%D1%83%D1%8E%20%D0%B3%D0%B8%D0%B4%D1%80%D0%BE%D0%B8 %D0%B7%D0%BE%D0%BB%D1%8F%D1%86%D0%B8%D1%8E%20%D0%BD%D0%B0%20%D0%BE%D1%81%D0 %BD%D0%BE%D0%B2%D0%B5%20%D0%B1%D0%B8%D1%82%D1%83%D0%BC%D0%B0%20%D0%BF%D1%80 %D0%B8%D0%BC%D0%B5%D0%BD%D1%8F%D1%8E%D1%82%20%D0%B4%D0%BB%D1%8F%20%D0%BF%D1 %80%D0%B8%D0%BA%D0%BB%D0%B5%D0%B8%D0%B2%D0%B0%D0%BD%D0%B8%D1%8F%20%D1%80%D1 %83%D0%BB%D0%BE%D0%BD%D0%BD%D1%8B%D1%85%20%D0%BC%D0%B0%D1%82%D0%B5%D1%80%D0 %B8%D0%B0%D0%BB%D0%BE%D0%B2

%D0%9E%D0%B1%D0%BB%D0%B0%D1%81%D1%82%D1%8C%20%D0%BF%D1%80%D0%B8%D0%BC%D0%B5 %D0%BD%D0%B5%D0%BD%D0%B8%D1%8F

%0A%D0%9A%D0%B0%D0%BA%20%D0%BF%D1%80%D0%B0%D0%B2%D0%B8%D0%BB%D0%BE,%20%D0%BF% D1%80%D0%B8%D0%BC%D0%B5%D0%BD%D0%B5%D0%BD%D0%B8%D0%B5%20%D0%B1%D0%B8%D1%82% D1%83%D0%BC%D0%BD%D1%8B%D1%85%20%D0%BC%D0%B0%D1%81%D1%82%D0%B8%D0%BA%20%D0% BE%D0%BF%D1%80%D0%B0%D0%B2%D0%B4%D0%B0%D0%BD%D0%BE%20%D0%B2%20%D1%81%D0%BB% D0%B5%D0%B4%D1%83%D1%8E%D1%89%D0%B8%D1%85%20%D1%81%D0%BB%D1%83%D1%87%D0%B0% D1%8F%D1%85:

- %0A

- %D0%94%D0%BB%D1%8F%20%D0%BA%D1%80%D0%BE%D0%B2%D0%B5%D0%BB%D1%8C.%20%D0%9C%D0%B0%D1%82%D0%B5%D1%80%D0%B8%D0%B0%D0%BB%20%D0%BF%D1%80%D0%B8% D0%BC%D0%B5%D0%BD%D1%8F%D0%B5%D1%82%D1%81%D1%8F%20%D0%BF%D1%80%D0%B8%20%D0% BE%D0%B1%D1%83%D1%81%D1%82%D1%80%D0%BE%D0%B9%D1%81%D1%82%D0%B2%D0%B5%20%D0% BC%D0%B0%D1%81%D1%82%D0%B8%D1%87%D0%BD%D1%8B%D1%85%20%D0%BA%D1%80%D0%BE%D0% B2%D0%B5%D0%BB%D1%8C%20%D0%B8%20%D1%80%D0%B5%D0%BC%D0%BE%D0%BD%D1%82%D0%B5% 20%D0%BA%D1%80%D0%BE%D0%B2%D0%B5%D0%BB%D1%8C%D0%BD%D0%BE%D0%B3%D0%BE%20%D0% BF%D0%BE%D0%BA%D1%80%D1%8B%D1%82%D0%B8%D1%8F.%20%D0%9A%D1%80%D0%BE%D0%BC%D0 %B5%20%D1%82%D0%BE%D0%B3%D0%BE,%20%D1%81%D0%BE%D1%81%D1%82%D0%B0%D0%B2%20% D0%BF%D1%80%D0%B8%D0%BC%D0%B5%D0%BD%D1%8F%D1%8E%D1%82%20%D0%B4%D0%BB%D1%8F% 20%D0%BF%D1%80%D0%B8%D0%BA%D0%BB%D0%B5%D0%B8%D0%B2%D0%B0%D0%BD%D0%B8%D1%8F% 20%D0%BC%D1%8F%D0%B3%D0%BA%D0%BE%D0%B9%20%D1%87%D0%B5%D1%80%D0%B5%D0%BF%D0% B8%D1%86%D1%8B%20%D0%B8,%20%D0%BA%D0%B0%D0%BA%20%D1%8F%20%D1%83%D0%B6%D0%B5 %20%D0%B3%D0%BE%D0%B2%D0%BE%D1%80%D0%B8%D0%BB%20%D0%B2%D1%8B%D1%88%D0%B5,% 20%D1%80%D1%83%D0%BB%D0%BE%D0%BD%D0%BD%D1%8B%D1%85%20%D0%BF%D0%BE%D0%BA%D1% 80%D1%8B%D1%82%D0%B8%D0%B9; %0A

- %D0%93%D0%B8%D0%B4%D1%80%D0%BE%D0%B8%D0%B7%D0%BE%D0%BB%D1%8F%D1%86%D0%B8%D1 %8F%20%D1%84%D1%83%D0%BD%D0%B4%D0%B0%D0%BC%D0%B5%D0%BD%D1%82%D0%BE%D0%B2.%20%D0%92%20%D1%8D%D1%82%D0%BE%D0%BC%20%D1%81%D0%BB%D1%83%D1%87%D0%B0%D0%B5 %20%D0%BF%D1%80%D0%B8%D0%BC%D0%B5%D0%BD%D0%B5%D0%BD%D0%B8%D0%B5%20%D0%B1%D0 %B8%D1%82%D1%83%D0%BC%D0%BD%D1%8B%D1%85%20%D1%81%D0%BE%D1%81%D1%82%D0%B0%D0 %B2%D0%BE%D0%B2%20%D1%82%D0%BE%D0%B6%D0%B5%20%D0%B4%D0%BE%D1%81%D1%82%D0%B0 %D1%82%D0%BE%D1%87%D0%BD%D0%BE%20%D0%BE%D0%B1%D1%88%D0%B8%D1%80%D0%BD%D0%BE %20-%20%D0%BE%D0%BD%D0%B8%20%D0%BC%D0%BE%D0%B3%D1%83%D1%82%20%D0%B8%D1%81% D0%BF%D0%BE%D0%BB%D1%8C%D0%B7%D0%BE%D0%B2%D0%B0%D1%82%D1%8C%D1%81%D1%8F%20% D0%BA%D0%B0%D0%BA%20%D0%B4%D0%BB%D1%8F%20%D0%B3%D0%BE%D1%80%D0%B8%D0%B7%D0% BE%D0%BD%D1%82%D0%B0%D0%BB%D1%8C%D0%BD%D0%BE%D0%B9%20%D0%B3%D0%B8%D0%B4%D1% 80%D0%BE%D0%B8%D0%B7%D0%BE%D0%BB%D1%8F%D1%86%D0%B8%D0%B8,%20%D1%82%D0%B0%D0 %BA%20%D0%B8%20%D0%B2%D0%B5%D1%80%D1%82%D0%B8%D0%BA%D0%B0%D0%BB%D1%8C%D0%BD %D0%BE%D0%B9%20(%D0%BD%D0%B0%D1%80%D1%83%D0%B6%D0%BD%D0%BE%D0%B9%20%D0%B8% 20%D0%B2%D0%BD%D1%83%D1%82%D1%80%D0%B5%D0%BD%D0%BD%D0%B5%D0%B9).%20%D0%9F% D1%80%D0%B8%D1%87%D0%B5%D0%BC,%20%D0%B8%D0%BC%D0%B8%20%D0%B3%D0%B8%D0%B4%D1 %80%D0%BE%D0%B8%D0%B7%D0%BE%D0%BB%D0%B8%D1%80%D1%83%D1%8E%D1%82%20%D0%BD%D0 %B5%20%D1%82%D0%BE%D0%BB%D1%8C%D0%BA%D0%BE%20%D0%BB%D0%B5%D0%BD%D1%82%D0%BE %D1%87%D0%BD%D1%8B%D0%B5%20%D1%84%D1%83%D0%BD%D0%B4%D0%B0%D0%BC%D0%B5%D0%BD %D1%82%D1%8B,%20%D0%BD%D0%BE%20%D0%B8%20%D1%81%D0%B2%D0%B0%D0%B9%D0%BD%D1% 8B%D0%B5; %0A

Bitumen-based material can be used for horizontal waterproofing of strip foundations

- Waterproofing floors. It is allowed to use mastic under the screed. In addition, the material is used for waterproofing basement floors, as well as balcony slabs.

This waterproofing is often used for bathrooms, garages, etc.; - Installation of waterproofing of swimming pools and terraces. As a rule, liquid rubber is used for these purposes.

Roof waterproofing with the material in question can be carried out provided that the slope angle does not exceed 30 degrees. The exception is liquid rubber, which can be applied to any surface.

Price

The prices shown in the table are valid in the spring of 2017:

Conclusion

We have explained to you what cold-applied bitumen mastic is, what types of it exist, and what qualities they have. Additionally, watch the video in this article. If you have any questions, write in the comments.

Bitumen roofing - modern and quality material, resistant to external influences. Unlike older types of coating, which can last no more than 5-10 years, current varieties demonstrate a significantly longer service life.

This occurs due to the use of a multilayer material, the basis of which is durable and load-resistant fabrics, and the binding layer is modified bitumen.

The advantages of such coatings include:

- strength, ability to withstand all operational loads

- durability - most materials last up to 30 years

- tightness, moisture resistance

- tightness of attachment to the base, which does not allow gusts of wind to tear off the covering fabric

- high sound insulation and heat-saving qualities

- maintainability, the ability to restore small parts without replacing the entire coating

The disadvantages of bitumen roofing are:

- most varieties require the creation of a substrate, which increases the cost of the entire roof

- appropriate conditions are required for installation. In particular, installation must not be carried out at temperatures below +5°C

The disadvantages of bitumen roofing are not so noticeable that users refuse to use it. The demand for the material is stable, and the wide selection allows each buyer to get the best option.

Roofing device: pie

Experts call a roofing pie a multi-layer package of materials laid under the finishing coating.

It usually includes:

- vapor barrier. Most often, this is ordinary polyethylene film.

- heat insulator. Soft or hard types of mineral wool, polystyrene foam, sprayed types, etc. can be installed.

- waterproofing or vapor waterproofing membrane. It is capable of transmitting water vapor in one direction, ensuring dry insulation

After these layers, a ventilation gap is installed, formed by slats. A continuous flooring made of OSB, plywood or other sheet materials is laid on top of it. fits on it underlay carpet, after which the bitumen roof is installed.

There is another design option. If so, there is no need for insulation. Therefore, the composition of the cake is much simpler - continuous flooring is laid directly on the rafters, followed by an underlay carpet and a finishing coating.

Types of bitumen roofing, pros and cons, cf. price per sq. m.

The name “bitumen roofing” is a general name for a fairly large group of coatings. They all have their own characteristics and properties. Among them are rolled and piece types of material. The first include:

Rolled

Ruberoid

This is the oldest type of bitumen coating and is currently used only on outbuildings or to waterproof certain structures during construction.

Uniflex

It is a coating with a durable base and modified bitumen as a binder layer. A layer of mineral coating is applied on top of it, which prevents the layers in the roll from sticking together.

Glassine

It is a type of roofing felt and is not used as a roofing sheet.

Bipole

The fiberglass base is impregnated with modified bitumen, resistant to ultraviolet rays. There is a layer of mineral coating on top.

Linocrom

This is a fiberglass base coated with bitumen lining.

Piece

Bituminous shingles

Piece types of bitumen roofing include bitumen shingles. It is produced in the form of separate sheets (shingles), which are overlapped and laid on the substrate and form a continuous and airtight coating.

A feature of bituminous shingles is their ease of installation and ease of installation on pitched roofs, which has significantly expanded the scope of application.

Prices

Prices for bitumen roofing are relatively low, but the overall price is quite high. Due to the need to install the substrate, the cost of 1 sq. m of coverage ranges from 400 ₽ to 3500 ₽.

List of types of bitumen roofing TechnoNIKOL

The Technonikol company is a leading supplier to the domestic market. Bituminous roofing is not the main, but very important part of the production. The range of materials is very wide and includes the following types:

- rolled materials (roofing felt, glassine, uniflex, bipol, linochrome)

- piece materials - bitumen

Flexible tiles are available in a wide selection of materials. They are combined into groups (collections) with several color options:

- Atlantic

- Continent

- Western

- Country

- Ranch

- Foxtrot

- Samba

- Rumba

- Modern

- Tango

- Quadrille

- Flamenco

- Salsa

- Bolero

- Chord

- Sonata

These collections differ from each other in the set of colors and the shape of the cutouts on the sheets. There are rectangular, jagged, wavy and other varieties. In the canvas they form a peculiar roofing pattern, reminiscent of traditional tiles.

Repair and auxiliary materials

In addition to roofing coverings, the Technonikol company presents repair and auxiliary materials used during installation or restoration of the main covering. For example, bitumen mastic for roof waterproofing is used both for pre-treatment, and in repair work.

In order to select the most suitable look bitumen roof, it is necessary to carefully analyze the conditions of its operation:

- temperature range

- solar intensity

- possibility of mechanical influences

- amount and intensity of precipitation. In particular, the amount of snow in winter and the frequency of its removal

- wind strength, possibility of hurricane gusts

- complexity of the roof configuration

- other features

Taking these criteria into account, the most durable and resistant material to all expected impacts is selected. It is important to understand that roll fabrics are generally less stable than piece materials. In addition, flexible tiles are much more convenient to repair and are able to adhere tightly and firmly to the substrate.

An additional criterion will be the installation method. If planned self installation, you can consider more expensive materials, but if you involve hired installers, the cost of coating will increase installation prices.

Installation and installation stages

Order installation work is described in detail in the manual that comes with the material. It must be carefully studied, since each coating has some features or nuances in installation. Procedure:

Preparing the base

The solid flooring must be cleaned of dirt, debris and dust. It is necessary to ensure that it is assembled correctly and that ventilation gaps and other necessary elements. If shortcomings are noticed, they must be eliminated immediately - then there will be no opportunity.

Laying underlay carpet

It is made parallel to the cornice line. On flat roofs or with a small angle of inclination it is mounted over the entire area. On roofs with large slope angles, they often make do with laying carpet only in the valleys, at the transitions of planes and other critical areas. Installation is carried out using roofing nails, all overlaps and joints are treated with bitumen mastic.

Installation of planks

Installation of end and eaves strips around the perimeter of the entire roof. They are nailed on top in a zigzag pattern.

Installing shingles

Laying shingles (sheets) starts from the middle of the cornice and goes to its ends. It is recommended to mix sheets from several packs together- this will help achieve uniform coloring of the entire roof.

The shingles (more precisely, their lower edge - the petals) are attached at a distance of 1 cm from the edge of the eaves and secured with roofing nails so that their caps are subsequently hidden by other sheets.

- the next rows are fastened so that the cutouts of the bottom row fall in the middle of the petals of the top. When the installation approaches the ends, the shingles are cut to size and glued to the eaves strips using mastic.

- laying the ridge part is done either with the same shingles with cut petals, or using metal or plastic ready-made elements from metal tiles

The installation procedure is simple, but requires accuracy and thoroughness. If the eye fails, it is recommended to make markings to guide the installation of subsequent rows of bitumen roofing.

Bitumen mastic

Bitumen mastic for roofing applied to joints, sheet overlaps or other critical areas. Sometimes it is applied as a continuous coating over the entire roof area. This makes installation more expensive, but provides high-quality waterproofing of the surface.

The material is poured onto a continuous floor and distributed evenly over the entire area. Before application, the mastic is thoroughly mixed in the container. If it is too thick, heating to a temperature of 60-80°C is allowed. Hot material must be used quickly, since when applied it quickly cools down and loses its fluidity.

Bitumen tape

Bitumen tape for roofing is a strip of material with an applied sticky layer, covered for the time being with a film. Used for sealing connections, protecting joints, insulation of the junction of the canvas to the cornice or wind strips.

This strengthens the coating and prevents the wind from tearing it off in a sudden gust. Another way to use it is to seal cracks, seams, and gaps during repair work. It is noteworthy that the bitumen tape does not have to be used in conjunction with bitumen coating, it fits on, ondulin, and other types of roofing.

Bitumen sealant

Bituminous roofing sealant is used to treat junctions, passage points through the roof and other critical areas.

The construction industry today offers the buyer a huge selection of roofing materials of different price categories and quality. At the peak of popularity are bitumen sheets made from synthetic fiber. It's comparative new material, but has proven itself to be excellent.

In this article we will look at the types of bitumen roofs and what are the features of installing a roof with soft tiles.

Distinctive features of bitumen roofing

Bituminous flexible roofing is one of the most popular roofing materials. This enviable consistency can be explained unique features coatings compared to other analogues:

High resistance to UF radiation and completely resistant to rotting.

Frost resistance, allowing the material to be used in almost any climate zone.

Moisture repellent.

Low flammability.

The bituminous material is not susceptible to corrosion and the development of fungal elements.

Excellent flexibility and softness, thanks to which bitumen can be used on roofs of complex geometric shapes.

Unpretentiousness of the roof. All that is required of the owners of such roofs is to inspect the surface from time to time.

The official guarantee from the bitumen roofing manufacturer is from 20 to 35 years.

Beautiful appearance. Due to the high strength of the coating, the color of the soft material does not lose throughout the entire period of operation.

High noise insulation.

Economical. The raw materials are different and not high in price compared to metal tiles or natural tiles, and a minimum amount of waste during installation.

Types of bitumen roofing materials.

Today, under the name bitumen soft roofing is hidden whole line roofing materials based on bitumen or bitumen-polymer. They are divided into 2 main groups: roll and piece coatings.

Rolled bitumen roofing:

Ruberoid. The material was obtained by impregnating cardboard with soft bitumen. Subsequently, the soft raw material was coated with especially strong bitumen to impart rigidity and durability.

Uniflex. Refers to modern modified roofing materials. Available in different modifications: polymer film, topping with coarse granules.

Glassine. Its technical characteristics are similar to roofing felt. They do not cover the roofs of houses; most often it is used as a vapor barrier.

Bipole – the coating is based on fiberglass, followed by impregnation with bitumen polymer. The bottom side of the raw material is covered with a polymer film, and the outside side is covered with coarse granules. They use soft bipole for sloping roofs of cottages. If the coating is applied for the purpose of repair, one layer is sufficient, if as a new base, double application is necessary.

Linokrom is a roof waterproofing material. Made from fiberglass. It is also impregnated with bitumen, but glued.

Piece bitumen roof

TO this species The material includes soft bitumen shingles or is also called soft roofing. Its structure is similar to roll types bitumen, but looks like a classic tile.

The elements are flat soft sheets small sizes with curly cutouts along one edge. Today you can find tiles of various shapes on sale - hexagons, simple rectangles, with wavy corners.

1 shingle consists of a reinforcing base not only impregnated with bitumen, but covered with it on both sides. On top of the coating is applied colored mineral powder, which protects the tiles from the effects of sunlight and maintains a beautiful appearance for many years. The bottom of the soft bitumen shingles is covered with a finer coating with a special protective film.

Bitumen shingles production technology

Not all bitumen roofing on the market is of the same quality. It is known that bitumen is originally a product of petroleum distillation. But there is bitumen, which is natural, i.e. released during weathering of oil. Only natural bitumen mass is used to create soft tiles High Quality. This coating is considered elite.

No bitumen is used in production pure form, it is softened to a temperature of 50 °C. There is another technology in which raw materials are heated to 90 °C. When heated to extremely high temperatures, the risk of losing the softness and durability of the final product increases. Polymers are added to the heated bitumen, which increase the service life of the bitumen to 30 years.

I use atactic polypropylene or styrene as polymer additives. The first roofing option is recommended for southern areas with a lot of sunny and hot days. At very low temperatures, such a coating loses its flexibility, and there is a risk of cracks forming on the roof.

A roof impregnated with a styrene modifier is recommended for northern regions with frequent snowfalls and strong winds. But such a coating requires additional protection against fading. For this you can use special protective compounds.

Application area

Roof roofing made from bituminous shingles can be assembled both for a new building and for an existing one. existing structure(the material allows installation on top of the old roofing). Externally, flexible tiles have a beautiful appearance, so they look great on large country cottages and small country houses.

Soft roofing can be used for roofs of complex shapes and can be easily mounted even on dome structures.

How to choose high-quality bitumen (flexible) shingles

Among large quantity It is easy for manufacturers of soft roofs to get confused and choose low-quality raw materials. Experts recommend that when purchasing, first of all, pay attention to the reinforcing layer. Particles of rot or traces of moisture are not allowed on it. According to European standards, for the reinforcement of soft bituminous tiles it is necessary to use a base made of fiberglass or fiberglass. Fiberglass fabric is 5 times stronger than fiberglass, but also much more expensive.

Important: in the technical characteristics of class 1 material, the density of the reinforcement should not be more than 110 g/m2. The optimal indicator, according to experts, is 125 g/m2, no more!

In addition to the reinforcing layer, it is important to pay attention to the external coating. It should not fall off when touched by hand. The coating not only ensures the aesthetics of the coating, but also reliably protects the material from external influence environment.

High-quality bitumen roofing is painted with basalt or slate granules at high temperatures of 800 °C. This method of dyeing allows the color to be preserved throughout the entire period of operation. There is no particular difference between the sprinkles. The strength of their adhesion to the bitumen itself is important. The best fixation is achieved by fractions of different sizes.

Important: manufacturers allow partial shedding of the roofing coating after 1 year of operation. There is no need to be afraid, the manufacturer takes this fact into account and covers the soft roof with a large amount of granules.

Installation features

Tile bitumen soft roofing has a number of installation restrictions. This coating can only be laid on a roof with an inclination angle of at least 12 degrees. This material not designed for standing water (there is a risk of leaks). Having chosen such a soft covering for the roof, you must take the preparatory work responsibly.

Important: lay soft tiles only on a solid sheathing!

All wooden elements sheathing and rafter system must be treated with special protective compounds. It is important to remember that bitumen does not spread fire, i.e. There will be no fire if a spark hits the roof surface. But if a fire starts in the house, then, unlike clay tiles or metal roofing, soft bitumen coatings burn.

If you have ever been involved in the construction or renovation of a private house, then you have definitely encountered the choice of high-quality building materials. Sometimes it can be very difficult to decide what material to choose for the roof of a private house. The main roofing materials that are used today in private housing construction are metal tiles, roofing sheeting, seam roofing, composite tiles, slate and soft tiles. In this article we will take a closer look at soft-bitumen shingles. It is also called flexible tiles for its plasticity.

The popularity of this type of coating is associated with the variety of colors, shapes and its wide design possibilities. Excellent for complex roofs. It consists of a base (fiberglass, thick cardboard or cellulose fabric), a bitumen binder and inorganic colored coating.

Types of soft roofing

| Manufacturer | Short description | Certificate | Rub. |

| Soft roofing Shinglas (TechnoNIKOL) |

Excellent roofing material. It is resistant to corrosion, has increased waterproofing, is easy to install, and is silent. The top layer is colored basalt topping. Presented in 14 collections and 75 shades. Warranty up to 60 years. Country of origin: Russia |

SHINGLAS Flexible tiles - Certificate of Conformity |

260-1261 RUR/m2 |

|

Modern reliable roofing material. ICOPAL is durable, fireproof, environmentally friendly. Does not deform under influence different temperatures. And also easy to install. The top layer is colored slate topping. Presented in 5 collections. Warranty - 25 years. Country of origin: Finland |

450-695 RUR/m2 | ||

| Soft roofing CertainTeed |

Bituminous single-layer and multi-layer shingles made from stabilized bitumen. Basalt granules are treated with a copper compound, which increases their resistance to fungus and mold. Installed on roofs from 9.5 degrees. Presented in 7 collections. Warranty up to 50 years. Country of origin: USA |

705-3393 RUR/m2 |

Characteristics of bitumen shingles:

Soft roofing consists of several layers:

- Grounds- fiberglass, thick cardboard or cellulose canvas.

- Bitumen binder- may include several types of bitumen. The most popular are oxidized, SBS-modified bitumen, PM-modified bitumen and APP-modified bitumen. Oxidized bitumen is artificially aged bitumen. main feature its highest heat resistance (up to 120 degrees). SBS-modified bitumen - artificial rubber is added to the bitumen mass. It improves material flexibility and strength at low temperatures. APP-modified bitumen - atactic polypropylene is added to the bitumen mass. This type of bitumen can withstand high temperatures, it is plastic and has good adhesive properties.

- Colored mineral chips— its main task is to protect bitumen from environmental influences.

Among other things, soft tiles differ in the options for cutting sheets:

- rectangle

- shingles

- hexagon

- "brick"

- "beaver tail"

- "dragon tooth"

Advantages of soft tiles

- Can be used when working with complex roof shapes

- The properties of this material do not change under the influence of temperatures

- Light weight, which greatly simplifies installation and facilitates transportation

- Fire safety

- With the correct calculation of the material, a minimum amount of waste remains after installation, which reduces costs

- Soft tiles are a moisture-resistant material

- Doesn't make noise in rain or hail

- If necessary, it is possible to make local repairs

- Widest selection of designs and shades

Prices in the online store

Comparison table with manufacturers

| A country | Country of Origin | min rub./m2 | max RUR/m2 | The basis | Bitumen binder | Top sprinkle | Roof angle | |

| Shinglas TechnoNIKOL | Russia | Russia | 260 | 1261 | fiberglass | basalt | 12° | |

| ICOPAL | Finland | Russia | 450 | 695 | fiberglass | SBS modified bitumen | slate | 11.3° |

| CertainTeed | USA | USA | 705 | 3393 | fiberglass | SBS modified bitumen | stone pavement | 9.5° |

| Tegola | Italy | Italy, Russia | 287 | 772 | fiberglass | PM-modified bitumen | basalt | 12° |

| Katepal | Finland | Finland | 439 | 1045 | fiberglass | SBS modified bitumen | stone pavement | 11.5° |

| Dock | Russia | Russia | 287 | 473 | fiberglass | oxidized, SBS-modified bitumen | basalt | 12° |

| Ruflex | Russia | Russia | 343 | 579 | fiberglass | SBS modified bitumen | basalt | 11.3° |

To perform proper installation, you need to purchase the following components for soft roofing:

- OSB3 (OSP-3) - oriented strand board with moisture resistance class 3. Designed for external construction work.

- Ridge-eaves tiles

- roofing nails

- Ridge aerator

- Snow stops for bitumen shingles

- Valley carpet

- Underlay carpets

- Mastic

- Metal strips

You can find all these materials on the Grand Line website, as well as in our online store.

Five advantages of cooperation with Grand Line

- Quality. All materials presented for sale on the company’s website undergo a thorough quality check.

- Guarantee. For all types of products Grand Line provides a written guarantee.

- Specialists. For any question, you can contact the company's employees. They will calculate the cost and quantity of required materials, help you decide on the coating and color, place your order and delivery.

- Choice. The company provides a wide range of products for every taste.

- Delivery. We provide transport and courier delivery in Moscow and throughout Russia.

It is difficult to say definitively which roofing material is the best. They are all good in one way or another. When choosing, you should take into account your budget, type of construction, color preferences and installation method. It is necessary to take into account the costs of constructing a reliable rafter system on which the final roofing material will be laid, and also include the cost of additional elements in the estimate. Choosing soft tiles, you can be confident in the quality and reliability of this material. It will give your home a beautiful finished look.