Installation of box gabions. Gabion - a many-sided element of decorative and protective structures Gabions installation instructions

Mesh structures filled with stone (universal modules for solving many construction or landscaping problems. By making gabions with your own hands and filling them with inexpensive local raw materials, you can save significant money. Specialized retail outlets sell ready-made gabion boxes of various shapes and sizes, but making them from scratch is not will require special skills.

How to make gabions yourself: step-by-step instructions

Necessary materials:

- masonry welded mesh with large cells;

- steel wire;

- stones for filling;

- black film;

- reinforcing bars (for high gabions).

- Tools:

- metal scissors or wire cutters;

- pliers;

- hoe;

- shovel;

- building level;

- roulette.

Stage 1. Site preparation

Thoroughly level the site for installing boxes using a hoe. Loose soil you can remove it by 15 cm and make a gravel cushion, carefully leveling the backfill.

The quality of leveling is checked with a long, even block or board, on which a building level is installed.

To prevent weeds from growing through gabion boxes, a narrow border is arranged along the border of the prepared area. guard groove 10-12 cm deep.

The area for gabions is covered black film for protection against weeds. Fill the groove with the edge of the film and press it against the side with a board.

Stage 2. Installation of boxes

Used as a mesh for gabions masonry welded mesh in sheets, purchasing material with the largest cells to save money.

DIY gabions step by step instructions. Photo

Advice: before starting production, determine what size stones you will fill the mesh with so that the cell dimensions do not turn out to be too large for small-sized aggregate.

The mesh is cut along the edges to create a box the right size. The intended bottom of the box is laid on a flat area, on four sides of it (side edges. The blanks are woven steel wire. The ends of the wire are carefully twisted with pliers to firmly fix the braid and prevent the edges from separating.

The side walls rise and intertwine with each other at the corners of the box.

In long boxes they are additionally installed cross panels to protect gabions from bursting. The panels are braided with wire with a bottom and side edges.

In tall structures everything internal corners At the junctions of the walls with each other and with the transverse panels, they are reinforced with 6-8 mm reinforcement rods.

Stage 3. Filling boxes

Various types of materials are suitable for internal filling. natural stone materials(rubble, cobblestone, pebbles, coarse crushed stone, quarry stone), as well as a mixture of several types. You can purposefully select a material that is contrasting in shape and color and, when filling, create an original composition.

how to make gabions with your own hands. Photo

When laying, the stones are selected so that they fit together as tightly as possible. To fill corners, it is better to select samples that have a straight or close to straight chip.

When laying, distribute large and small stones so as to fill the voids as much as possible.

Advice: if part of the stone ends up smaller size cells, lay it inside the gabion, and place it near the walls large pieces. You can also hide ugly samples inside the box.

Stage 4. Making the second row

For tall retaining walls or fences, one row of boxes is usually not enough. In this case, a box is installed on top of the first level, mounted according to the principle described above, including the installation of transverse panels and reinforcing ties, and it is also filled with stone.

Tip: Gabions integrate perfectly with waterfalls, mailboxes, benches, country shower, foci. If you are planning them for additional functional use, then before filling the boxes, secure the necessary objects to outside or lay inside engineering Communication V steel pipes that will not be crushed by stones.

how to make gabions step by step. Photo

Gabion fence. Photo

DIY gabions. Video

How to make a country pond with gabions

Summer residents have enough earthworks in the garden, and few are inspired to dig a bed for an artificial pond. But if you make a pond at your dacha with gabions, you will only have to dig 15 cm for a site whose diameter exceeds outside diameter reservoir the width of the paved path. The site is pre-leveled.

pond with gabions. Step by step instructions

The shape of the decorative pond can be any, since the mesh is easy to cut and bend. In our example, the pond is round with an internal diameter of 146 cm, a height of 50-60 cm. Capacity (500 liters. Gabions are made of mesh with cells 100x25 mm. It took 270 kg of large and medium-fraction stones to fill

WaterproofingThe pond is made of black film, which lines the bottom and inner walls. Part of the film is wrapped inside the box and temporarily fixed with clothespins until the gabions are completely filled.

Attached to the pond bed area 100x30 cm, 50-60 cm high. For the bed, a larger mesh with cells of 100x50 mm was used. To fill it, 190 kg of stone of the same fraction as for the body of the pond was needed. The gabion for the bed is made with a lid to lay the wooden boardwalk, slightly hanging over the pond.

A decorative pond with gabions at the dacha is intended for summer use; the water is drained for the winter. If you provide additional aeration or regular water changes, you can keep ornamental fish or plant aquatic plants in it.

Ideas for using gabions

The use of gabions is possible both functional and decorative, up to the creation landscape sculptures complex shape. But if for last option necessary artistic ability, then the set useful ways use is simple and effective.

Gabion fences

The advantage of gabion fences is their massiveness, durability and the ability to create a fence, gradually increasing the height. You can complete the work in short steps, without specifically allocating entire days or weeks. And the availability large number cheap stone will reduce costs to a minimum

DIY gabion fence. Photo

Gates and wickets can be wooden or metal. Give original design fencing can be done by combining boxes with transparent metal sections or a decorative top made of wood or forged metal.

Tip: Easy to integrate with gabion fences landscape lamps, but preliminary installation of the cable inside the box in durable pipes will be required.

Gabions in country house arrangement

For summer residents, mesh boxes with stones can save a lot of effort and time during arrangement. Self-made gabions are used as:

- bases for benches and deck chairs;

- fencing of any height for open areas;

- garden screens and zonal partitions;

- walls for the gazebo;

- supports for canopies;

- lawn fencing;

- stand for table top;

- base for barbecue or hearth;

- poles for landscape lights;

- base for an artificial fountain or waterfall.

Some examples of implemented ideas are presented in the photo. In fact, any task that requires the construction of a powerful foundation or wall can be implemented using gabions

Strengthening slopes and banks with gabions

Owners of plots on a slope or along water bodies can strengthen the slopes and coastal line with retaining structures based on gabions. Adjoining stairs can also be made from gabion boxes. Since such structures are in active contact with water, we recommend choosing galvanized mesh for gabions, which better resists corrosion.

strengthening the shore with gabions with your own hands. Photo

Tip: to prevent the boxes from clogging with soil or sand, cover the side in contact with the ground with film or geotextile. Don't forget to make a drainage ditch behind the retaining wall.

Gabion flower beds

Landscaping (another area of application for gabions. The ease of manufacturing meshes of any height and shape allows you to use mesh structures as a border for large flower beds, a kind of flowerpot for one large plant or several small ones, a stand for flower containers, a fence for a tree

DIY gabion flowerbed. Photo

Gabion flowerbeds easily integrate with benches, fences, and retaining walls. This allows you to effectively use the site, placing more useful areas on limited area. And the mesh fence itself easily becomes a support for hanging plants planted nearby.

Tip: Use homemade gabions to create raised, warm beds to grow good harvest vegetables

Ease of manufacture and ample opportunities The use of gabions has become the reason for their popularity among summer residents and private homeowners, who appreciate the versatility and economic benefits of arrangement with mesh structures.

Not so long ago, what a gabion was was known only to a fairly narrow circle of specialists. But today, gabion structures are increasingly used for the design, arrangement and strengthening of houses, and many people want to know about their calculation and application.

1 What are gabions and how are they made?

Gabion structures have been used to strengthen and protect road embankments, soil slopes, engineering structures, river banks, reservoirs and seas for more than 100 years. Today, when they began to be used in private housing construction and landscape design, the question of what a gabion is is asked not only by specialists in the above fields, but also by ordinary people. This is a frame made of metal mesh and filled completely with stone or other filler. Frames of the required size are fastened together with wire using a stapler or other tool and the result is a structure of the required height, length and shape.

According to GOST, for the manufacture of gabions, twisted wire mesh with regular hexagonal cells of certain sizes, made of low-carbon steel wire, must be used general purpose. But the production of gabions currently also involves the use of mesh with a different shape and cell size, when guided by the calculation of the strength of the entire structure and the impossibility of stone spilling out of it. The wire can be single or double, uncoated, galvanized, with a PVC sheath or with a colored polymer coating. Mesh boxes are assembled using galvanized wire or brackets (galvanized rings). In the latter case, a pneumatic or manual stapler (gun) is used.

Welded gabions are also made, which are a structure assembled from steel rods of different diameters (pergons) or (geogrids). The stone for gabions or other filler must be sufficiently durable, waterproof and frost-resistant, crushed natural or artificial. Another important requirement– stone for gabions should be a ready-to-use material and not require additional processing, as this will lead to an increase in the cost of the gabion structure. You can purchase ready-made mesh baskets or order them specific goals. Before their manufacture, a calculation of the entire structure is made.

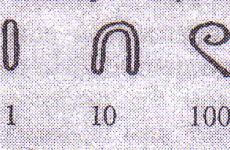

The design of large-sized gabions requires a more complex calculation and may differ slightly from the design of ordinary small ones. Their design is supplemented with diaphragms - dividing partitions. Based on their geometric shape, gabion baskets are divided into three main types:

- box-shaped - most often with dimensions 1.5x1x1 m, 2x1x1 m and the so-called Jumbo with dimensions 3x2x0.5 m, 2x1x0.5 m;

- cylindrical;

- flat (mattress-mattress) – the most common are mattresses Renault(rectangular flat size 3x2 m, thickness 0.30, 0.23, 0.17 m).

2 Main types of gabion baskets and structures

Currently there are many various types gabion baskets, differing in size, shape and price. However, gabions are in greatest demand today, especially during the construction of various high enclosing structures. Maccaferri, produced by the company "Officine Maccaferri" (Italy). Features of their designs:

- the presence of reinforcing membranes in the boxes;

- variety of shapes and sizes;

- are delivered to the site disassembled, in the form of packages, and are assembled directly on site into three-dimensional structures using special ribs and tied with wire or fastened with a stapler.

Maccaferri gabions are made from a mesh with 6-gonal cells, woven from double twisted wire. Box-shaped gabions are most popular - they are in the highest demand.

No less famous are mesh baskets Geofast, produced Russian company"GEOFAST". These three-dimensional mesh structures are also produced in various shapes and sizes from a mesh with hexagonal cells woven from double twisted wire. The mesh can only have a zinc coating or be additionally protected with a layer of PVC. An innovative Galfan coating is also used, which provides the greatest protection for Geofast baskets from corrosion. The scope of application of Geofast structures is quite wide:

- water management - strengthening the banks with gabions;

- road construction - strengthening slopes and slopes of roads;

- instead of concrete structures– capital strengthening of slopes with gabions, protection from avalanches, rockfalls, mudflows, etc.;

- as weights when ensuring the protection of pipelines laid under water;

- other.

The universal fencing systems of pergons - welded gabions - deserve special attention. They are made in the form of lattice steel boxes with various fillers (processed glass, pebbles, stone, crushed stone, concrete slabs, wood and much more). These systems are installed directly on the ground or on the foundation.

A fence made of gabions Pergons as in the photo consists of:

- The supporting structure is usually pillars equipped with flanges at the bottom, which are attached to the base with anchors or dowels. Optimal material racks - rod 8–10 mm thick or according to calculations.

- Power grid - can, for example, be made of galvanized rod 5–6 mm thick (or according to calculations).

From pergon structures you can create not only a gabion fence, but also:

- flower beds and beds;

- interior decoration and facade of the house;

- decorative and garden elements as in the photo: gazebos, labyrinths, obelisks, artificial ponds, arches and other design elements.

3 Installation and installation of gabion structures

The technology for laying gabions is not very complicated, but requires compliance with a number of instructions. Laying and installation of gabions is carried out on a prepared base - just level the surface. The stone for gabions and the mesh for them are supplied separately. Mesh baskets are assembled according to the attached instructions:

- the material is unpacked, laid out on a hard, flat surface, and then straightened out;

- a box is constructed from the material - bent vertically side panels, the corners of which are connected to each other with wire or a stapler.

After this, gabions (empty without filler) are installed on the pre-planned ground surface. Then the installation of gabions continues in the following sequence:

- the installed baskets are fastened together into a solid structure, pre-designed in accordance with the calculation of strength and reliability;

- stone for gabions is placed in the resulting structure - the largest fractions are along the edges and down, and the smallest ones are in the middle;

- filled baskets are closed with a lid, which is secured with wire or a stapler.

Behind the terrible word “gabions” there is a very useful thing for construction. Retaining walls on sloping areas, terracing the area, strengthening river banks, strengthening slopes and eliminating accidents on reservoirs, as well as non-standard decorative elements on the site - all this is done using gabions. Depending on the size and shape, certain gabion structures are used for different purposes. In this article we will talk about the types of gabion structures, what requirements are put forward for them and how to install gabion structures.

Types of gabion structures

Gabion structures are mesh containers filled with stones. Containers can have different sizes and shapes. Depending on the shape, certain structures are used for different purposes.

There are three types of gabion structures:

- Box-shaped;

- Cylindrical;

- Mattress-mattress.

In addition to structures for strengthening slopes, stabilizing soil erosion, bank protection, strengthening the foundation road surface gabion structures are used by designers in purely decorative purposes, without forgetting, however, about functionality. For example, recently the construction of fences, fencing, etc. from gabions has gained popularity. garden benches and tables.

Box gabions are parallelepiped-shaped containers. Their sizes can be different: width from 1 to 2 m, length from 2 to 6 m, height from 0.5 to 1 m. For greater structural strength, reinforcing diaphragm panels are installed inside the containers, placing them at a certain distance from each other.

Box-shaped gabions are made in two ways:

- The first is made of galvanized steel mesh with hexagonal cells, which is attached to a rigid frame.

- The second is welded from steel rod or wire.

Welded structures are more rigid and are considered more durable. They also look more aesthetically pleasing, making them ideal for use in landscape design. For example, for erecting fences from gabions, arranging benches and tables, framing artificial slopes, etc.

Box gabions are used to form retaining walls of varying complexity and sizes. For example, where slopes slide and erode, where flooding or river bank overflows occur. Box-shaped gabions are also used to strengthen banks and dams, as well as for terracing the site. Another use case is laying out foundations for lightweight buildings.

You can also make gabion structures with your own hands. To do this, you will need a chain-link mesh, steel rods with a diameter of 6 - 8 mm and galvanized steel wire with a diameter of 3 mm. A rigid frame is formed from a steel rod, the Chainlink mesh is stretched over it, and the mesh is fastened with wire to the frame rods.

Cylindrical gabions are cylindrical in shape and have greater flexibility due to the absence of stiffeners. Such gabions are a candy in the form of a cylinder 2 - 4 m long with tails on the sides. The diameter of cylindrical gabions varies from 0.65 m to 0.95 m. They are made of double-torsion steel mesh.

Gabions cylindrical used to strengthen coastlines, to eliminate accidents on dams and reservoirs, as well as to construct dams. They can also be used to arrange the bases of retaining walls and to protect against erosion.

Flat mattress gabions or mattress-mattress gabions, as they are sometimes called, differ from box-shaped ones in that they are made with a small height of 20 to 30 cm. Typically, their width varies from 1 to 2 m, and their length from 1 to 6 m. The most common height is 0 .23 m.

The main difference between mattress gabions is that, due to their low height, they can easily follow the shape of the terrain of the site. They are used to line canals and dams, slopes, slopes and to equip the foundation of hydraulic structures. Another way to use mattress gabions is to arrange the foundation for structures made of box gabions.

Elements of gabion structures and requirements for them

Gabion structures are manufactured at enterprises in accordance with GOST and TU. All structural elements must meet certain requirements. And the product itself must be manufactured after careful calculations for strength, torsion and other loads.

One of the main elements of gabion structures is a double torsion mesh. It is made from the following types of wire:

- Wires with zinc coating of at least 250 g/m2.

- Wires with reinforced anti-corrosion coating. For example, Galfan is 95% zinc and 5% aluminum.

- PVC coated wires.

The dimensions of gabion structures may deviate from the nominal ones by 5%, but no more.

In addition to the wire that is used to weave the mesh, gabions also use knitting wire, with which the mesh is attached to a rigid frame. Certain requirements also apply to it:

- Breaks in the binding wire are not allowed.

- The ends of the wire can be spliced by twisting.

- The ends can also be spliced with an extension.

- The twist length should not be more than 20 mm.

- The number of such twists should not be more than 1 piece per 20 m2.

Please note that when arranging gabion structures, the size ratio of the wire used in the mesh, edge and bundle must be maintained. You can get the exact data from the table.

Stones - which ones can be laid in gabions

Gabions can be filled with various stones, both polished and cornerstones from quarries. The size of the stone must be such that it cannot fall through the cell in the gabion mesh. The most optimal sizes are considered to be 1d - 2d, where d is the diameter of the cell in the grid. Don't use stones bigger size, since then too large voids will form between the stones.

Important! Gabion filler stones measuring 1d - 1.5d are best suited as they provide a more uniform settlement around the entire perimeter and area.

Requirements for stones - fillers for gabions:

- Heaviness. Specific gravity not less than 17.5 kN/m3 - for work on land, not less than 23 kN/m3 - for hydraulic work.

- Frost resistance is higher than MP350.

- Strength not less than 400.

- Low water absorption less than 0.6%.

- Resistant to decay. The maximum weight loss should be 5 - 10%.

- Hardness.

- Minimal reduction in strength when saturated with water. The softening coefficient must be at least 0.9, and for sedimentary rocks - at least 0.8.

What stones can be used to fill gabions can be seen in tables 2, 3 and 4.

Geotextiles

Geotextiles are used in the construction of gabion structures as a return filter. Previously, crushed stone and sand bedding was used for this. The use of geotextiles can reduce the required sand layer by 20%.

The geotextile fabric is water-permeable, thin and flexible, does not rot, does not form mold, and is resistant to rodents, insects and root germination.

Geotextiles help with fast and high-quality clogging of porous structures. Due to clogging of rocks, structures made from gabion structures acquire exceptional strength.

Canvases of this material are delivered to the construction site in rolls. It is necessary to check whether the canvas is solid and there are no tears. When arranging structures, the canvas can be cut and laid with an overlap of 10 - 20 cm. The sections of the canvas are sewn or glued together to make the connection strong enough.

Installation of gabion structures - box gabions

You can build structures from gabion structures on your site yourself, although much depends on the complexity of the project. For example, it is still not worth the risk of constructing a retaining wall on the shoreline of a deep river on your own. More simple designs, such as, retaining walls on a slope, terracing, fences and fencing can be done with your own hands. First of all, you need to buy ready-made gabion structures, order 15% more geotextiles than needed for the project, and stock up on such tool:

- Pliers.

- Wire stapler.

- Hammers.

- Mounts.

- Anchors or wooden stakes.

To prepare the site, you will also need a shovel or excavator.

Box-shaped gabion structures come from production folded, tied together in bags. Gabions can only be transported and stored in a horizontal working position. Be sure to check compliance with storage and transportation conditions. The height of such a stack should not exceed 2 m. Install a stack with gabions on wooden base- supports to avoid damaging the lower structures.

How to assemble a box gabion:

- Open the package with gabions.

- We separate one gabion and lay it out on a flat horizontal surface. Bottom related parts: side walls and straighten and unfold the diaphragms.

- We check whether all elements of the gabion have smooth edges and whether they were bent during transportation.

- If the gabion elements are not connected to the bottom, then it is necessary to tie the side walls, rear and front walls and diaphragms to the bottom of the structure using a knitting wire.

- The diaphragms should be located in increments of approximately 0.75 m. We connect them to the walls.

- To fasten the elements with binding wire we use a stapler.

- Raise the side walls, back and front so that a box is formed.

- Then we connect the tops of the corners with thick frame wire. It should stick out from the corners of all panels.

- We check whether the tops of the corners of the box are at the same level.

- We connect the panels together, starting from the tops of the corners. We use knitting wire. This must be done in a special way: we alternate a single loop and a double loop with a pitch of 120 - 150 mm.

The gabions are tied using a stapler; it connects the structure with galvanized rings. A stapler is one of the main tools you will need when installing gabions. It can be pneumatic or manual. The latter is autonomous, but the pneumatic one is connected to electricity, although it is easier for them to work.

After collecting several empty gabions, they must be placed in the required position according to the plan. The area for this should already be prepared.

- We install box-shaped gabions in a row.

- If there is a possibility of the structure slipping, it is necessary to secure it. To do this, we drive in rods or stakes or anchors from one side.

- It is advisable to fence the front side with formwork.

- We tie the gabions together in all corners and touching edges.

- When installing gabions in two or more rows, they must be placed “face to face” or “back to back”. The panels are connected to each other and to the reinforcing wire, which is located on the edge.

If gabions are installed in several levels, floors, then the upper gabions, unfilled with stones, must be firmly tied around the entire perimeter, in the corners, as well as in the places where the diaphragms touch.

Filling gabions with stones

What stones can be used to fill gabions has already been described above. Let us only add that in addition to large specimens, smaller stones can be used, but they total share should not exceed 5 - 7%. Small stones must be placed in the middle of the box. Filling of gabions is carried out both manually and mechanized. But manual loading is preferable, since the stones can be laid out and settled more efficiently. It is also worth remembering that you cannot drive heavy equipment on gabion structures.

- The stones must be laid tightly so that there is a minimum of voids between them.

- We leave the last gabion empty so that it can be connected to new unfilled gabions.

- If the height of the box-shaped gabion is 1 m, it must be filled in 3 stages. First fill it 1/3 full. Then we fix the walls with knitting wire. In fact, we are organizing spacers that will keep the structure from crawling under the weight of stones.

- Then we fill the next third and secure it with a spacer again.

- When filling the last third of the box, it is necessary that the level of the stones be 2 - 5 cm above the top edge of the box. When rock settlement occurs, the stone will settle flush with the edge.

Important! The arrangement of spacers prevents the walls and stone material from “bulging out”. To tie the box horizontally, you need to thread the wire through 2 - 3 cells, then insert an object, for example, a board, between the ends of the wire, and rotate this object. This is shown more clearly in the photo below demonstrating gabion structures.

If the height of the gabion is 0.5 m, then it is filled in two steps.

Securing the cover

The gabion cover should be secured with special care. You can tie it with either knitting wire or staples using a stapler.

- We tie the lid in the corners so that it does not fidget or move further.

- We firmly tie it to the reinforcing wire at the edge of the frame.

- We tie the lid around the perimeter to the frame of the box.

- Finally, we connect the cover to the diaphragms.

If suddenly a stone interferes with tightly connecting the lid to the frame, it can be moved to the middle of the box.

In curved sections, when installing gabion structures, they will have to be cut so that the final structure is strong enough and at the same time accurately follows the curved line of the project.

- We lay out the gabions so that they overlap each other, forming a curved surface.

- We cut off the excess overlapped part of the gabion structure with scissors.

- We assemble gabions according to the project.

You can also cut gabions to height, for example, at the end part. After trimming and filling with stones, a lid is placed on top and firmly tied to the trimmed box.

Cylindrical gabion structures are supplied in bags with already cut sheets, along the edges of which reinforcing tension wire is threaded. After the bundle of gabions has been unpacked, it is necessary to lay one of them out on a flat surface, straighten it, and check for defects.

Using wire threaded through the edges, we tighten the mesh into a roll - a cylinder. One edge must be immediately tightened tightly. To fill with stone, leave a gap between the long longitudinal edges. After filling with stone, carefully pull the second edge and tie it.

After this, we tie the longitudinal edges together.

In the case of using cylindrical gabions with high level water or strong current, they can simply be dumped into the water using a crane or rolled down a slope.

The technology for installing mattress-mattress gabion structures is very similar to the installation of box-shaped gabions, so much of the further instructions will be familiar to you. We will describe similar moments only briefly.

- We lay out the gabion, straighten all the edges and elements.

- We lift the side walls and diaphragms and tie them in the corners.

- Raise the back and front walls. We tie them to the diaphragms so that the reinforcement wires of the diaphragm and sidewalls engage with each other.

- Checking the plane of the structure.

The lower edge of the diaphragms must be connected to the bottom, if this was not done in production.

Formation of a structure or structure from mattress gabions

Mattress structures are laid on top of geotextiles. This must be done extremely carefully so as not to damage the geotextile fabric.

After the gabions are folded into the required position or structure, they must be tied together. We remember that linking should be done when the gabions are empty.

Important! The shorter 2-meter side of the gabions is installed upward if the site has a slope. To secure them in place, anchors or wooden pegs are used, which are driven from the inside of the box under the very edge that needs to be held in place.

Filling mattress gabions with stones

The general rules for filling mattress gabions are similar to those for box gabions:

- The minimum size of the stone should not be less than the cell size.

- It is necessary to fill 2 - 5 cm more.

- Lay with minimal voids.

The only difference that can be highlighted is that mattress-mattress gabions can be filled with stones that lie on a slope either from below or from above. Also note that for gabion heights of 0.17, 0.23 and 0.30 m, horizontal struts are not required.

Anchoring

On steep slopes mattress gabions are firmly fixed to the ground using anchors. How this is done is clearly shown in the photo. If the slope is soft soil, then the anchors must be driven in during the installation of gabion structures and left after all work is completed.

Securing the cover

We securely connect the lid to all diaphragms and side walls. Please note that the cover must be connected not only along the contour, but also with all the reinforcing wires and diaphragms.

If the mattress gabions are laid in a row and filled with stones, you can cover them as if with one lid. To do this, cover them with a double torsion mesh cloth. The width of the canvas should not exceed 2 m. The length can be taken equal to length designs. We connect the cover cloth with all the necessary elements.

Curvilinear sections using mattress gabions are made in exactly the same way as with box gabions. The laying and cutting technology is no different.

Something unusual I would like to highlight is that mattress-mattress gabions can be laid in the designed position already filled. For example, when developing a coastline, gabions can be collected and filled in close proximity to the shore. A geotextile sheet can be fastened to the bottom of the structure. Then the finished structure is installed in the required position using a crane. Moreover, this can be done both from the shore and from a boat. But this technology no longer belongs to the “do-it-yourself” category.

Reading time ≈ 12 minutes

Installing gabions is simple, effective and original way improve the area. Making such a design will take no more than a day, but the result will be simply amazing. In our article we will give step-by-step instructions for creating gabions from mesh with your own hands.

Low gabion fence.

History and device

First, let's figure out what it is and what gabions look like in the photo. Translated from French the word gabion means "big cell". Initially, gabions were used in military affairs (since the 16th century) for the construction of fortifications. In the 19th century, builders paid attention to such structures and began to use them in the construction of roads, bridges, dams, to strengthen slopes and river banks as a strengthening element. Today, gabions have become a popular element in landscape design; they are classified as small architectural forms(MAF).

Gabions are structures of various shapes, made of a metal frame and filled with stones.

Strengthening a steep slope.

Many centuries ago, the frame of gabions was wicker baskets made of wicker, but now the frame of the products is made of galvanized wire of single or double weave with a hexagon-shaped cell. The gabion box is not monolithic - it is divided into sections thanks to partitions (diaphragms). Thanks to this feature, the blocks acquire greater variability when installed - they can be used to build structures of various shapes.

Design advantages:

- Flexibility and resistance to deformation. Since the structure is made of wire, it acquires high ductility. Even with serious ground movements, the structure may deform slightly, but serious damage or deformation is not terrible.

- High strength, reliability.

- Durability. Thus, such elements can last for several decades, maintaining a beautiful appearance.

- Weather resistant.

- Effective sound insulation.

- High water throughput.

- Low cost in comparison with other materials of similar purpose.

- Easy to install. This does not require any special skills, tools or equipment. In addition, if necessary, containers can be disassembled, moved to another location and refilled.

The design fits perfectly into the design of areas of different styles and consists of environmentally friendly natural materials, It has universal application- This undeniable advantages gabions, which explains their great popularity and widespread use

Fence made of wood and gabion.

Usage and Functions

In modern times, gabions are used in landscape design as decoration or for their intended purpose - as a strengthening element. Product functions:

Decoration of borders.

The structures can also be used to create noise insulation if the site is located close to a road with active traffic. Inside the cavities of the gabion you can hide wiring or a hose for irrigation.

If the appearance of gabions seems boring and the same type, they can be supplemented LED backlight– in the evening and at night, such elements will look truly fabulous!

Illuminated gabions.

Materials

As we have already indicated, the main materials for making a gabion are metal carcass and stone. But there are many nuances that are worth considering. Let's take a closer look.

Frame

The frame must be strong enough to withstand the weight and pressure of heavy stones. The following materials are used for its manufacture:

Frame made of twigs.

Filling

Stone is the main material for filling structures. The choice of stone type depends on the purpose and location of the structure. Can be used as natural views, and artificial analogues. This takes into account their size, shape, and composition. For underwater structures, hard rocks of volcanic origin are chosen, for example:

- granite;

- basalt

- quartzite;

- diorite.

Gabion with flat stones.

It is important that stones for ground use are durable and resistant to weathering, and in particular - low temperatures and differences. The following types are used for this:

- sandstone;

- gray-pink granite;

- crystalline schists;

- porphyrite

River stones and pebbles are also used for filling - due to the streamlined shape of the stones, such decorative elements look very impressive. As a rule, one type of stone typical for a given region is used to fill the frame - in this case, the structure does not look too colorful and fits perfectly into the landscape. You can also order multi-colored stones, but the cost of the finished product will be higher.

Idea: gabions with alternative filling will look original and unusual - wooden saw cuts, multi-colored glass, broken brick, concrete or tiles, pieces of tree bark and cut polypropylene pipes.

It is important that the size of the stones exceeds the size of the mesh cells by at least 30%. For underwater structures, the stone should be twice as large as the holes on the frame.

Gabion with glass filling.

A couple more examples of designs with alternative filling:

Gabions with alternative filling.

Forms

Most often, designs have the correct geometric shape in the form of a box - this is the most used type. But flat and cylindrical types are also common. In the photo below you can see what the types of gabions look like:

Types of gabions.

Flat varieties (so-called mattress) effectively protect the landscape from erosion and erosion. They are also used as a basis for massive box-shaped structures. Cylindrical (another name is gabion bags) are used to strengthen the foundation of structures located under water. Also used as decorative element when designing gardens and parks.

In addition to those listed standard designs Products of irregular shape, stylized to resemble various objects, are popular. So, from wire you can twist the most different figures: people, animals, objects. Such elements perform a purely decorative function and look very impressive in the design of the site.

Gabions of unusual shape.

Spiral-shaped snail gabions are popular:

Gabion snail.

To decorate the site, structures in the form of balls are often used. They harmoniously combine with waterfalls, ponds, rockeries and alpine slides.

Gabion balls.

What shape to make a gabion depends entirely on your imagination, goals and skills. However, designs of any complexity look equally beautiful on the site. Next, we will look at step-by-step instructions with photos for creating gabions with your own hands from a chain-link mesh for flowers and other materials.

Manufacturing

Making such a design is not at all difficult.

Necessary materials:

- sand and cement for mortar;

- crushed stone or gravel;

- metal pipes for support posts;

- fastening elements: bolts, clamps, nuts;

- gabions (structure made of rods);

- wire;

- protective agents for covering the frame (zinc paste or others);

- frame filler.

Important! IN pure form Chain-link mesh is not used to create gabions - it does not have a sufficient level of strength and rigidity.

Scheme of construction of a gabion with a concrete foundation

Tool:

- level;

- rope or twine, pegs;

- shovel (hoe);

- wire cutters and pliers;

- container for mixing concrete;

- lath length from 1.5 m.

Master class step by step:

Manufacturing process.

Tip: the corners of the structure can be strengthened by beating metal profile. This is especially important for large, tall structures.

It is advisable to make large gabions not monolithically, but from smaller blocks. Each block can be created according to the principle described above, the only difference is that the next block will be attached not to the soil, but to the top cover of the lower block.

The technology of filling the frame with stones has some nuances. How to do this step by step:

- Fill the frame halfway.

- The walls of the product will diverge slightly. They need to be pulled together. It is important that the design is symmetrical, so try to ensure parallelism of the walls. For tightening, you can use braces made of thick, strong wire.

- Next you need to fill out top part frame.

- Finally, the walls of the gabion are tightened at the top according to the same principle.

Filling the structure with stones also needs to be done according to the rules. Select stones in shape and size so that they fit snugly against the mesh and each other, and sharp corners didn't stick out. Unpresentable specimens can be hidden deeper. If significant voids form between the cobblestones, fill them with smaller stones. For corners, whenever possible, select specimens with right angles. With this approach to filling ready product will look neat and attractive.

Step-by-step technology for filling gabions with filler

Tip: if the gabion is quite wide, you can use a trick to save money on filling it. It is worth laying out the space along the walls with stones, and filling the inside of the frame, invisible to the eye, with unnecessary building materials(for example, pipes) or construction waste, covering it with geotextiles.

Gabion snail

Let's look at another master class on creating a cute snail gabion. The design itself is designed in the form of a spiral made of double mesh (distance up to 10 cm). You can choose the dimensions yourself, but usually such spiral structures are up to 1 m high and slightly more than 1 m wide.

Gabion in the shape of a snail.

So, for manufacturing you will need the following materials:

- galvanized mesh with small size cells (up to 3 cm);

- metal rods with a cross section of up to 10 mm;

- galvanized binding wire;

- filler (any small stone - gravel, crushed stone, pebbles, etc.)

- soil (up to two dozen buckets).

Step-by-step production:

- Free the plot of land selected for the construction from debris, roots, and plants.

- Do a preliminary fitting - arrange a piece of mesh in a spiral to estimate the height and diameter of the structure.

- Using metal scissors, give the mesh the desired shape. It is important to bend the ends to avoid injury from them. Since the spiral is double, it is necessary to cut out two identical parts.

- The metal rod needs to be cut into pieces. First, we need two 100 cm sections. They need to be driven into the ground to a depth of about 20 cm, keeping a distance between them of about 10 cm - this distance between the grids will need to be maintained for the entire duration of the spiral.

- It's easier to start working with the first grid. Using wire, it must be attached to the reinforcement. Next, arrange it into a beautifully shaped spiral, drive in pieces of reinforcement of smaller height every 40-50 cm, and attach the mesh to them.

- Using the same principle, you need to attach the second part of the mesh. First, they need to be connected with a narrow piece of mesh. Finally, make a metal fence from the mesh.

- Throughout the entire length of the spiral, the mesh must be tied with hooks (see photo) at the top, middle and bottom every 30 cm, otherwise the stone may burst the mesh.

- Next, the space between the grids is filled with stones. Finally, the space in the middle is filled with soil.

Process in stages.

Using step-by-step instructions and photos, you can make gabions of various shapes for flowers and not only with your own hands from chain-link mesh and other materials.

The view below shows the process of installing gabions with your own hands: